Company Advantages1. EcoPura beverage production process is consist of several major parts. It is designed with an actuating device, speed variator, gearing, working device, brake device, lubrication system, and cooling system. The product is widely used for commercial applications

2. OEM/ODM services for our beverage processing are supported by our rich R&D experience. The dimension of this product can be customized according to needs

3. The product has good structural strength. Its yarn has been finely treated with various agents to enhance its weaving performance. The product has the advantage of low failure rate

4. The product can run under extreme conditions. All its components and the electrode leader are inflicted with a certain electric pressure to test its voltage resistance and insulation performance. The product is carefully designed with all NSF approved components

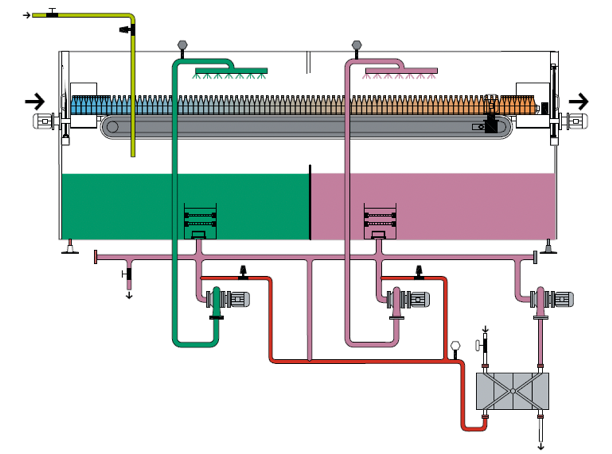

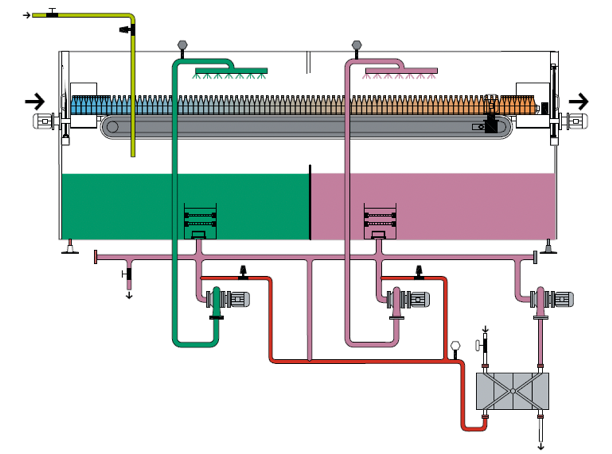

Cooler

The tunnel cooler designated for adjusting the temperature of the Hot filled products to ambient temperature by cool spraying system and thereby ensuring that no distorting their taste or color,

♦ Spraying nozzle system for quick and defined bottle treatment

♦ Clean design in stainless steel AISI304

♦ Efficient cooling performance thanks to even water distribution and snap-in spraying system

♦ Controlled by SIEMENS PLC & HMI and Frequency controlled drive system

EcoPura has expanded its business into oversea market.

2. With great service and excellent product quality, not only have we won the overseas markets, but we have also been rewarded praises from domestic and foreign customers.

3. Always following the vision of beverage processing , EcoPura aims to be the leading manufacturer in this industry. Contact us!