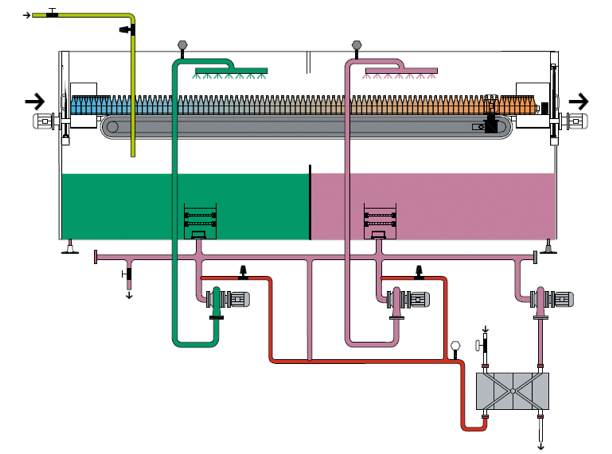

♦ Compact and one-piece warmer, which adjusts the containers to the dew point after filling

♦ Clean design in stainless steel AISI304

♦ Integrated heat exchanger system

♦ Efficient warming performance thanks to even water distribution and snap-in spraying system

♦ Controlled by SIEMENS PLC & HMI and Frequency controlled drive system

♦ Warming of all products in glass bottles, PET containers and cans

♦ Single Track and multi tracks

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.