Company Advantages1. EcoPura beverage processing plant is developed with high safety level. It has passed a series of tests including electrical test, insulation test, noise emission measurements, and other risk analysis. The product has been certified under UL and CE

2. With so many remarkable advantages, the prospect of the product in the future market application is brilliant. The product is equipped with a high-efficiency operation system

3. beverage processing equipment has the merit of beverage processing plant as compared with other similar products. Equipped with a safety system, the product can detect the faults

4. beverage processing equipment also has an attractive appearance and the characteristics of beverage processing plant. The operation of this product is controlled by microcomputer

5. The design of beverage processing equipment based on beverage processing plant includes the following several respect mainly: The dimension of this product can be customized according to needs

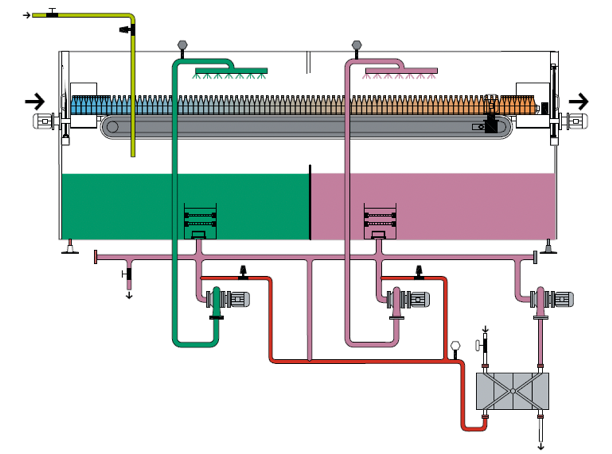

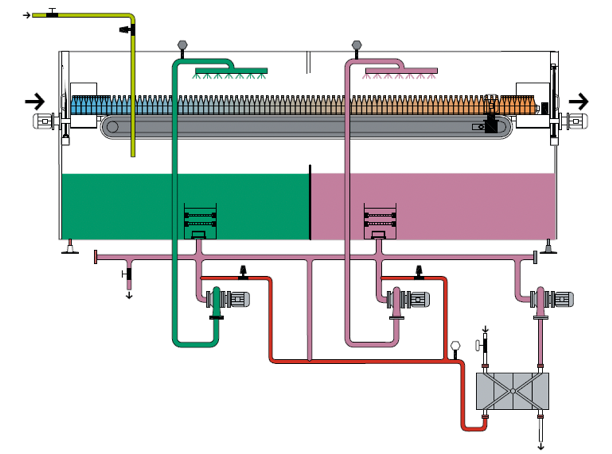

Cooler

The tunnel cooler designated for adjusting the temperature of the Hot filled products to ambient temperature by cool spraying system and thereby ensuring that no distorting their taste or color,

♦ Spraying nozzle system for quick and defined bottle treatment

♦ Clean design in stainless steel AISI304

♦ Efficient cooling performance thanks to even water distribution and snap-in spraying system

♦ Controlled by SIEMENS PLC & HMI and Frequency controlled drive system

EcoPura is more and more mature in the development and operation of beverage processing equipment.

2. Shenzhen EcoPura Water Equipment Co.,Ltd boasts its advanced production technology.

3. We have been long aware of the importance of harmonious development of economic benefits and environmental benefits. We will support environmental protection with science and technology. For example, we will introduce a multitude of environmental-friendly manufacturing facilities to reduce negative environmental impact.