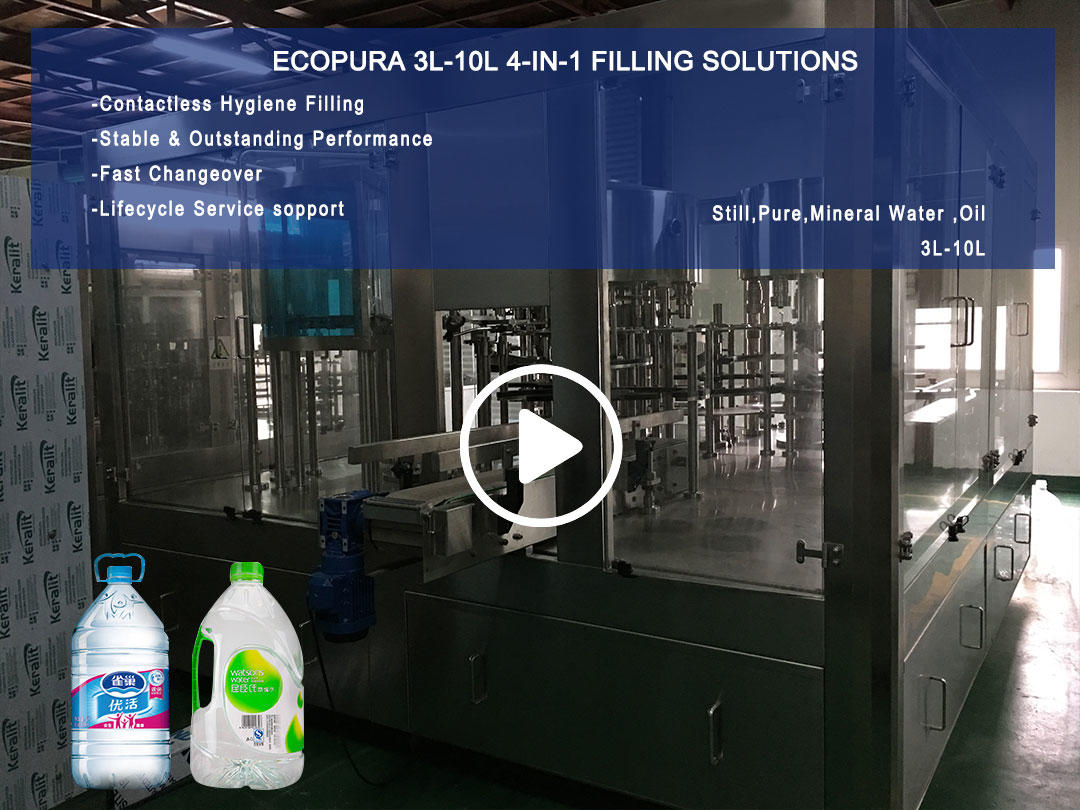

ECOPURA 4-in-1 PET 3L-10L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral, still water and other liquids etc

Model | Bottle Spec | Capacity Cal@5L | Power | PLC & HMI |

HSG10-10-5 | 3L-10L | 1200-1500bph | 2.2kw | SIEMENS |

HSG12-12-5 | 1500-2000bph | 3.0kw | ||

HSG14-14-5 | 2000-2500bph | 4.0kw | ||

HSG16-16-5 | 2500-3000bph | 5.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Why 4-in-1 ?

Twin bottle rinsing station include chemical water rinsing and Ozonated water rinsing ensuring the performance with strict hygiene standard

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us.

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination

The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Transaction record with our foreign customers:

Application:

This machine is mainly suitable for automatic filling and screw capping of essential oil, electronic cigarette liquid, eye drop, nail polish, eye shadow, etc.

Machine function and feature:

1. This machinea dopts mechanical arm toscrew caps, equipped with automatic sliding device, to prevent the cap damaging.

2. Peristaltic pump or piston pump filling system, measuring precision, convenient manipulation.

3. Filling system has function of suck back,prevent the liquid leak through.

4. Color touch screen display, PLC control system, no bottle no filling.

5. Main electrical elements adopts foreign well-known brand.

6. Machine body is made by 304 stainless steel, easy to clean, machine is full compliance with GMP requirements.

Bottle sample:

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.