Company Advantages1. Shenzhen EcoPura Water Equipment Co.,Ltd supplies carbonated soft drinks filling machine with soda filling machine features in various specifications.

2. This product is hypoallergenic. The comfort layer and the support layer are sealed inside a specially-woven casing that is made to block allergens.

3. The product has good tensile strength. Some non-toxic chemical agents such as softener are used to enhance the stretching force between fibers.

4. Shenzhen EcoPura Water Equipment Co.,Ltd fully implements ISO9001:2000 quality management system.

5. Due to the comprehensive sale network, the carbonated soft drinks filling machine of EcoPura has got its wide attention overseas.

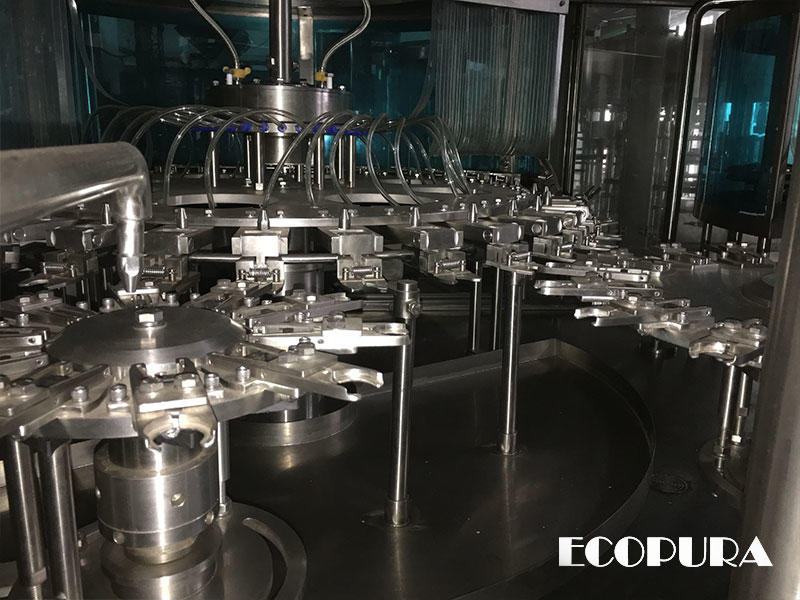

ECOPURA 3-in-1 PET 0.3L-1.5L DHSG-series monobloc equipped with isobaric filler nozzles designated for filling carbonated beverages such as Cola, beer, carbonated water and other liquids etc

Model |

Bottle Spec |

Capacity Cal@500ML | Power | PLC & HMI |

DHSG16-12-6 | 0.33L-1.5L

Height:150-330mm

Dia: 50-115mm |

3000-3500bph |

1.8kw | SIEMENS |

DHSG24-16-6 | 4000-5000bph | 2.2kw |

DHSG24-18-8 | 5000-6000bph | 2.2kw |

DHSG24-24-8 | 8000-9000bph | 3.0kw |

DHSG32-32-12 | 10000-12000bph | 5.5kw |

DHSG38-38-14 | 12000-15000bph | 7.5kw |

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. |

High quality & Strict Hygiene

Production of top-quality beverages requires conditions of strict hygiene, All parts that comes into contact with the beverage are manufactured in Stainless steel 304 or 316

Contactless filling

SIEMENS PLC & Touch Screen control with Integrated and separate electro-pneumatic components

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316. hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Filling Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene.The PET container is first pressed on by the PET lifting unit and pressurised afterwards. Once the same pressure is in the ring bowl and the PET container, the filling valve will be opened and the filling process starts. The liquid is gently fed via a swirl insert into the bottle. Two different filling speeds guarantee optimum flow behaviour. A flow meter monitors the fed liquid quantity. Once the exact filling volume has been reached, the flow meter provides a signal and the valve closes electro pneumatically Maximum flexibility − Filling of non-carbonated and carbonated products on one system Maximum filling accuracy − Precise determination of fill quantity via inductive flow meter Gentle product treatment during filling − Low-foam and low-turbulence filling vias wirl insert in the valve

Hygiene and stable filling processes − Separate gas channels for pressurization and snifting

ECOPURA filling machines in their standard version are suitable for CIP and beverage mixer

Capping Part

The capper is most precise part ensuring the machine to run credibility and product quality.

The capping head applies the cap. The cap is pressed onto the bottle by means of spring pressure. At the same time it is screwed onto the thread of the bottle neck finish. As soon as the rotation is ended and the required tightening torque is applied to the cap, a hysteresis clutch ends the capping process.

All main parts made of stainless steel AISI304

Pick station with adjustable height

Torque and spring force of the capping head are adjustable

Flushable cap retainer

Motorised height adjustment of the capper top part with bottle selection feature

Caps online Sterilization

ECOPURA dedicated in every process details to control the hygiene such as for the caps sterilizing to ensure the maximum hygiene for your all kinds beverages. Caps online sterilizer made of stainless steel 316L with built in spraying device for high pressure Ozonated pure water sterilizing

Shenzhen EcoPura Water Equipment Co.,Ltd engages in the production of carbonated soft drinks filling machine , including soda filling machine .

2. Whenever there is any problems for our csd filling machine , you can feel free to ask our professional technician for help.

3. Everything we do is guided by the principles of excellence, integrity, and entrepreneurship. They define the character and culture of our company. Inquiry! Our sustainability policy lays out the commitments we will undertake to ensure our positive contribution to sustainability. We work to decrease greenhouse gas emissions, energy consumption, solid landfill waste, and water consumption in our operations. Our company is committed to climate action, including reducing energy demand and greenhouse gas emissions associated with our products and operations. Regardless of the political perspective, climate action is a global issue and a problem for our customers to demand solutions. Inquiry! We support sustainable management to back up our company's long-term viability. We will make our production progress to be compliant with environmental regulations or conform to sustainable policies and initiatives.