Company Advantages1. blow moulding process 's material is controlled to be just right.

2. Compared with the traditional blow moulding process , bottle blow molding machine has a series of advantages.

3. This kind of product can improve the working efficiency of work staff. The operation process is very simple and convenient.

4. High working efficiency and labor-saving are the forte of the product. People like to use it to improve production income.

4800-7200bph 0.1L-2L Servo blow molding machine 4EL 6EL

EPC-4EL,6EL Blower mainly used for blowing Water/CSD/Juice beverage bottle, Oil bottle ,condiment bottle ,cosmetic bottle and other packaging containers

Model | EPC-4EL | EPC-6EL |

Mold Cavities | 4 | 6 |

Speed | 4800-5000bph | 7200-7500bph |

Bottle Size |

Up to 2L | Up to 2L |

Bottle Height | <330 mm | <330 mm |

Bottle Neck |

Φ18-Φ38 mm |

Φ18-Φ38 mm |

Bottle Body Diameter |

Φ106 mm |

Φ106 mm |

Working Pressure | 7-9kg/cm | 7-9kg/cm2 |

Low Pressure Air Consumption | 2000L/min | 2000L/min |

Blowing Air Pressure | 25-35kg/cm2 | 25-35kg/cm2 |

High Pressure Air Consumption | 6000L/min | 8000L/min |

Heating lamp | 48pcs | 72pcs |

Installation Power | 96kw | 110kw |

Practical Power | 30-50kw | 40-60kw |

Machine Size | L4.5m*W2.2m*H2.6m | L5.8m*W2.2m*H2.6m |

Weight | 6500kgs | 10000kgs |

♦ Servo Control all process

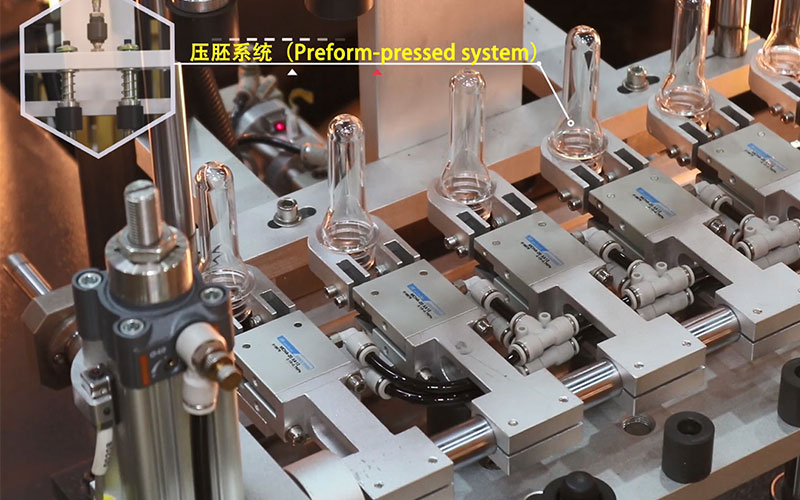

♦ Electrical components are World famous brand: FESTO, Schneider, Omron etc

♦ Visibility, maintainability, standardized components, Safety

♦ A Scrap rate of under 0.1%

♦ Up to 99% production efficiency

♦ Changeovers in less than 30mins

♦ Oven electrical consumption cut by up to 25%-30%

♦ Compressed air saving up to 20%-25%

Based on years of manufacturing experience, Shenzhen EcoPura Water Equipment Co.,Ltd has grown into a competitive manufacturer of bottle blow molding machine in the industry.

2. Our advanced machine is able to fabricate such blow moulding process with features of [拓展关键词/特点].

3. We are committed to being an ethical, value-based corporate citizen operating in a fair and legal way in every market, through respecting human rights, operating through a sustainable supply chain. Please contact us! Attaching high importance to common development, we incorporate ourselves into promoting the communities' development. Our poverty-relief programs have been conducted to drive local economic growth. We have adopted the policies for sustainable resource utilization. We enhance the environmental management system constantly by determining, realizing and revising environmental goals periodically in order to meet the requirements of our environmental awareness. Through developing and implementing key programs, we aim to minimize the impact of our operations on the environment by understanding and mitigating against our material impacts.