Model | EcoSL100 | EcoSL150 | EcoSL250 | EcoSL400 |

Capacity | 100b/min | 150b/min | 250b/min | 400b/min |

Label Height | <250mm | <250mm | <250mm | <250mm |

Label Material | PVC, PET, OPS, PE, R-PET, PLA, PP | |||

Label Thickness | Ranging from 15um to 130um | |||

Containers Spec | Suitable for bottle size up to 2Liters with dia ranging from 50-100mm | |||

Power | 3kw | 3kw | 3kw | 4kw |

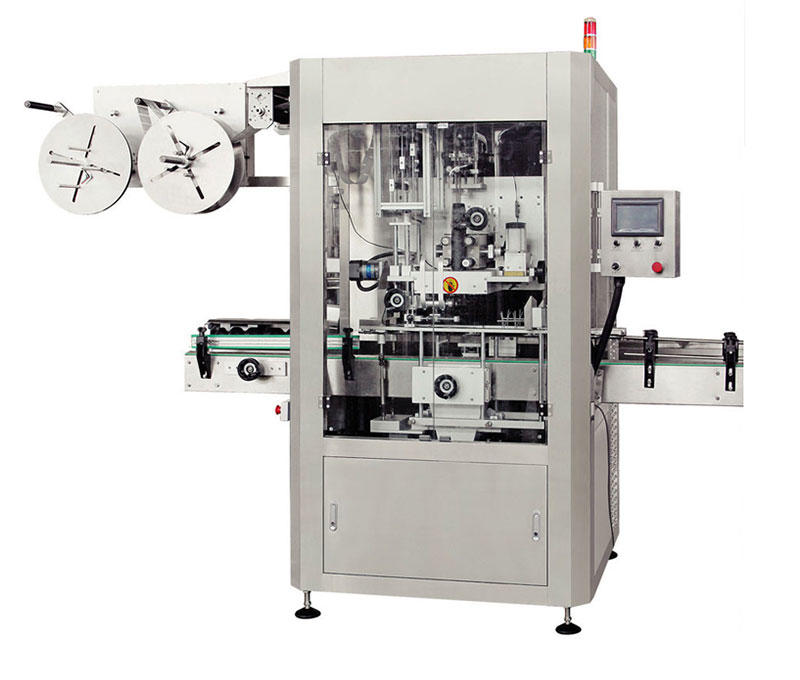

♦1.The infeed worm spaces the incoming containers to the pitch.

♦2.The flat sleeve film is unwound from the reel in the sleeve supply unit.

♦3.The deflection rollers in the sleeve supply unit function as a buffer.

♦4.The feed rollers convey the sleeve film from the sleeve supply unit to the sleeve applicator.

♦6.The opened sleeve is precisely cut to the desired length by a servo-controlled cutting unit.

♦7.Two servo-controlled rollers accelerate the sleeve and apply it over the container.

♦8.The downstream brush system ensures that the label is precisely fitted.

♦1.The containers with sleeves applied to them are fed through the steaming tunnel.

♦3.The nozzle bars supply the steam to the sleeve from the bottom upwards..

♦4.The sleeve shrinks under the impact of the heat and adapts to the shape of the container.

♦5.The finished, sleeved container leaves the steaming tunnel.

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.