Company Advantages1. EcoPura water filling machine for sale has been tested for quality. All its main components, including the gears, pistons, engines and other moving parts, are tested to meet our established standards.

2. There is sufficient strength inside this product. Force analysis is performed prior to manufacture to find the forces acting on each element. And the best-suited materials are chosen to withstand these forces.

3. This product meets the requirements of safe use. Safety testing has been performed based on mechanical design/performance, the intent of the product, the conditions of use and more.

4. One of our customers bought 50 pieces for the first time and repurchased for more after he sold them out very quickly in his small gifts shop.

5. People who bought this product will praise that it has a long service life and they don't have to frequently replace it.

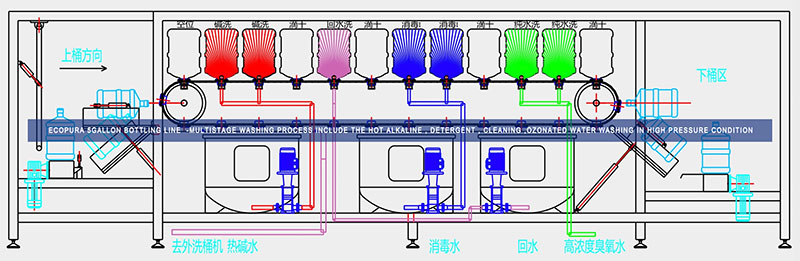

ECOPURA 5gallon bottle washing filling capping machine HSG600 with capacity 600bph.

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

Bottles Sterilizing & Washing

Exclude the brusher pre-washing process for cleaning bottles inside & outside part, the pre-washed 5gallon bottles feed into the 3-in-1 washing filling capping unit which Designed Multistage high-pressure inner washing Process include Hot Alkaline washing, disinfection water washing, Dripping ,Ozonated pure water cleaning for ensuring the recycled bottles 100% clean & health, the washing system is controlled by pumping though cleaning tank and the ejecting nozzles on the bottle carrier to spraying the inner wall of the bottles by high pressure water, after finishing the washing process, the bottles will discharge though reverse turn-over mechanize and transported to the filling Part for full filling as designated volume and finally capping, discharge out the 3-in-1 by conveyor to next step

Caps Loading & washing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine .Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Rotary Filling & Capping

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Shenzhen EcoPura Water Equipment Co.,Ltd is a specialized enterprise with manufacture, product injection, and product processing in a whole.

2. The production process of water bottling equipment is strictly controlled by our strong technical force.

3. By introducing advanced machines and technologies, EcoPura aims to be an excellent bottled water machine manufacturer. Get price! Shenzhen EcoPura Water Equipment Co.,Ltd regards quality support as the core competitiveness. Get price! EcoPura considers the prevalence of filling equipment is based on its top quality and specialist support. Get price!