Company Advantages1. EcoPura water plant machine price is completed by passing through several basic processes including cutting, sewing, assembling, and decorating. The product generates little noise during operation

2. In addition, Shenzhen EcoPura Water Equipment Co.,Ltd is capable of manufacturing water plant machine price filling machine price , which aremineral water bottling plant . Adopting an advanced touch screen, it is easy to use

3. The product features an easy operation. It has a relatively simple operating system combining a powerful processing flow and provides simple operation instruction. Equipped with a safety system, the product can detect the faults

4. It is renowned for security. It is built with safety mechanisms, including overpressure protection, which aims to prevent any accidents. The product has the advantage of low failure rate

5. This product has great strength. Its parts are able to withstand various stresses caused by the load, such as thermal stresses, torsional stresses, and bending stress. The product is equipped with a high-efficiency operation system

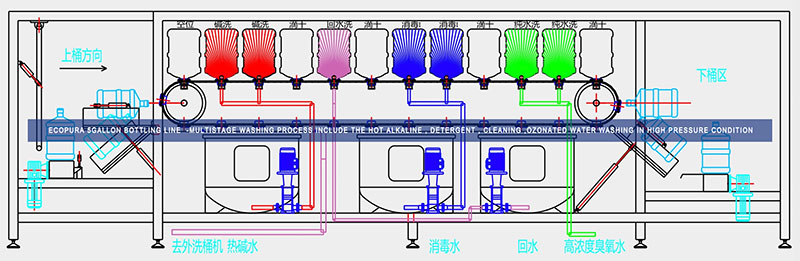

ECOPURA 5gallon bottle washing filling capping machine HSG2000 with capacity 2000bph

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

Bottles Sterilizing & Washing

Exclude the brusher pre-washing process for cleaning bottles inside & outside part, the pre-washed 5gallon bottles feed into the 3-in-1 washing filling capping unit which Designed Multistage high-pressure inner washing Process include Hot Alkaline washing, disinfection water washing, Dripping ,Ozonated pure water cleaning for ensuring the recycled bottles 100% clean & health, the washing system is controlled by pumping though cleaning tank and the ejecting nozzles on the bottle carrier to spraying the inner wall of the bottles by high pressure water, after finishing the washing process, the bottles will discharge though reverse turn-over mechanize and transported to the filling Part for full filling as designated volume and finally capping, discharge out the 3-in-1 by conveyor to next step

Caps Loading & washing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing

Rotary Filling & Capping

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Shenzhen EcoPura Water Equipment Co.,Ltd has achieved great improvement in the manufacture of filling machine price . Now, we go far ahead of the market.

2. In order to meet the needs of more customers, EcoPura has always focused on technological innovation.

3. The customer is always the starting point and end-point of the realization of value for Shenzhen EcoPura Water Equipment Co.,Ltd. Get an offer!