ECOPURA 5gallon bottle washing filling capping machine HSG600 with capacity 600bph.

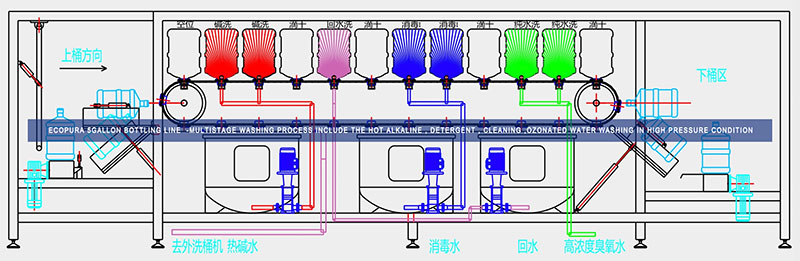

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine .Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Factory Price Automatic Liquid Filling Machine/ Water Sachet Packing Machine/Milk Pouch Packaging

PRODUCT DESCRIPTION:

This machine is high precision packing machine and the most advanced liquid compound packing machine in China, which is standing, three side sealing and intermittent.

It can automatically complete Bag-making, filling, sealing, printing, cutting and counting .Controlled by microprocessor and automatic photocell.

It is widely used to pack all kinds of liquid without gas, especially soy, wine, vinegar, juice, soybean milk, peanut oil, vegetable oil, plant oil, mineral water and liquid chemical products.

Film developed width(mm) | 320 240 160 |

Packing capacity(ml) | 200-500 70-350 40-180 |

Production Efficiency | 1500 or 2000 bags/hour |

Application Voltage | 380v or 220v |

Horse power | 1.2kw |

Machine weight | About 650kg |

Overall dimension | 1050×750×1900MM |

1. Automatic Bag Liquid Filling Machine (3-10L)

Parameter:

JYX-YB2000 | |

Capicity | 600-900pcs/h |

Filling volume | 3L-10L |

Power | 220V 50Hz |

size of main machine(mm) | 1090 ×1500×2000 |

Feature: | 1) With PLC controler 2) Automatic filling,sealing,sliting 3) Convenience for drinking and portable 4) With automatic conveyor belt, automatic leak detection |

MORE PRODUCTS:

PRODUCT SHOW:

Wholesale Price Semi Automatic Chocolate Cream Filling Machine For Honey Dosing Filler Machine

| Product name | Small manual pressure filling machine |

| Working speed | 20-40 times / minute |

| Total Weight | 10kg |

| Filling nozzle diameter | 7mm×8mm (inner diameter × Outer diameter) |

| Filling range | 0-50ml (External knob for adjustment) |

| Dimensions | 340 × 340 × 780 mm |

| Filling accuracy | ±1% |

| Hopper volume | 10kg |

Packaging & Delivery

1. Packaging Detail: standard export wooden case package or carton.

2. Leading time: 1-3 days

3. Delivery time: depend on ways of shipping

FAQ

1.Can you make customized items?

Yes, customized service is acceptable we here

2.When can I get the quotation?

We usually quote within 24 hours after we get your inquiry.If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

3.What's the payment term?

We accept Paypal ,Ali pay, credit, westem union,TT and so on.

4:Shipping & payment

1. ways of shipping:

1) Small machine will shipped by express (DHL, EMS, FedEx and so on) or air

2) Big order and big machine shipped by sea (FOB Shenzhen/CIF)

2. payment methods

We accept LC, TT, West Union , Papal or MoneyGram

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.