ECOPURA 5gallon bottle washing filling capping machine HSG600 with capacity 600bph.

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine .Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

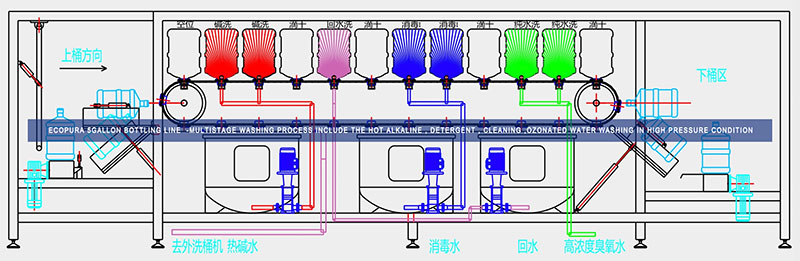

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Good news:

We understand buyers might be worried about ordering products from China.

Now our company have joined Alibaba Trade Assurance . By placing order through Alibaba, if the suppiler doesn't meet your contract requirements for on-time shipment or Pre-shipment product quality, Alibaba.com may refund the payment as stated in your contract.

Now our Trade assurance Limit is up to 128000USD. You can check this information from shamoquan.en.alibaba.com

And if you worry about the machine quality, you can ask Alibaba to find a trusted third party like TUV,SGS, etc. to inspect the quality for you. This way protects the buyer's interests and lowers your risk.

Contact person : Ms.coco zhu

Website: http://www.fillingmachine.cn

Website on alibaba.com: shamoquan.en.alibaba.com

Telephone: 0086-750-3230696

Fax: 86-750-3230887

1) Capacity: 300 bottles per hour (18.9L bottle)

2) 5 gallons bottle washing, filling and capping machine controlled by PLC

3) Conveyor with motor, bottle loading and unloading system

4) Two lines, 6 washing steps with hot detergent, hot water, and pure water

5) Washing bottle inside and outside

6) adapted to PC & PETbottles

7) Imported electrical parts and cylinders

8) the luxury type: with inner and outer bottle washing together, with curtains to avoid pollution during different washing process; with temperature controller to control the temperature of washing water and with output counter to tell the daily & annual capacity

9) Stainless steel 304, imported famous electrical appliances.

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.