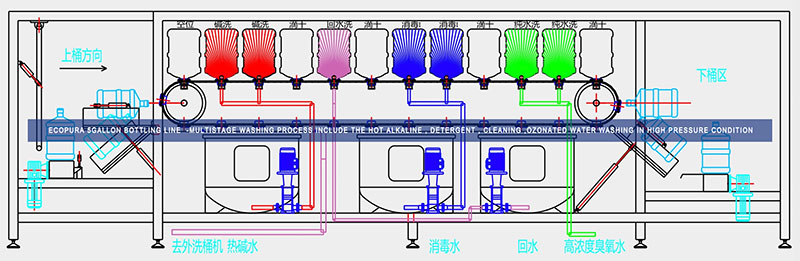

ECOPURA 5gallon bottle washing filling capping machine HSG100-HSG450 with capacity 100-450bph.

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Clean bottles are discharged out of washing part to filler. After entering the filler, bottles are filled contactless with qualitatively control.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Packet packing plastic strip machine price for filling equipment company

Product Description

Product Application and Bag Type

Vertical form-fill-seal packing machine is suitable for articles that are easy to crush and not easy to measure automaticlly, such as potato chips, choppes slices, casserole, jelly, dumplings, etc.

Technical Parameters

1) Imported PLC control system and color touching screen enable easy and efficeint operation

2) The bag type is diversified, and it can provide customers with pillow-shoaped bags, gusset bags, hanging hole bags, and even bags

3) Imported servo film transport system, imported color standard sensor, accurate positioning, excellent machine performance and beautiful packaging

4) A variety of automatic alarm protection functions are used to minimize losses

Product structure

Working Process

1st step: Setting the parameters you want by touch sreccn

2nd step: Put the material into the bucket chain conveyor

3rd step: The date printer will print the product date, expiry date and product number on the film

4th step: The 304 stainless steel bag former will shape the bag

5th step: The sealing device will seal and cut the bag automatically

6th step: Then you will get the nicly packages

Packing Film

Our semi veritical packing machine can use various of pcaking film like OPP, OPP+CPP, PE, PET+PE, Aluminum metallized films etc.

Optional device

Our company

Foshan Dession Packaging Machinery Co.,Ltd is located in nanhai district, foshan,It is a collection of research, production, sales and after-sales service as one of the production-oriented enterprises.Machines are widely used in food, articles for daily use, hardware industrial products, medical supplies, hotel one-time items, etc. Along with the continuous development of science and technology, the level of automatic packing machinel is higher, scope will be wider.

Packing & Delivery

Sealed packaging will be wrapped in Outer packaging is no fumigation Guangzhou China Shenzhen China

the machine. wooden box

1.T/T and Western Union are accepted

2.30% deposit before production and 70% balance before shipment

3.All banking charges outside China are on buyers

1.Upon receipt of payment , delivery date will be in 15-30 working days,

2.By Air, by Sea or by Express (DHL etc)

3.Shipment cost will depend on the destination, shipment way and the weight of the goods

FAQ

Yes, not only manual or operation video, 3D drawing also available to make as per your design,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market.

Please note our above business license and certificate. And if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine installation and assist you till the end.

Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

Yes. Please offer us your final destination, we will check with our agent to see if it available, and most of the area is ok for us to clearing and sending in your countries.

——Our advantages——

Products advantages | 1. We always give top priority to quality 2. Strictly guarantee the precision of parts error 3. Reasonable processing technology coupled with advanced processing equipment |

Trade advantages | 1.Our company is a Gold Supplier on Alibaba. So we can provide Escrow Service on Alibaba. 2.Our company can do Trade Assurance Order for customers on Alibaba. |

Custom made advantages | 1.The company independent research and development, custom design exclusive for the series of products. 2. Mutual benefit with the best quality and service, and sincerely hope that friends from various circles at home and abroad sincere cooperation and mutual benefit and win-win situation. |

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.