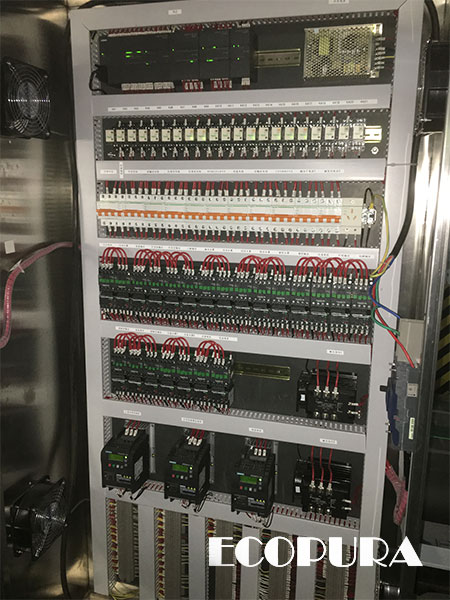

Company Advantages1. EcoPura bottle filling machine price is designed under the vigilance of our talented and professional designers. Adopting an advanced touch screen, it is easy to use

2. EcoPura is recognized as the premier bottle filling machine price provider in this industry. The operation of this product is controlled by microcomputer

3. The product achieves a better heat dissipation effect. It is specially designed with a temperature higher than the surroundings to transfer heat by convection, radiation, and conduction. The product is equipped with a high-efficiency operation system

4. The product is proven to be free of the dangers of electrical shock. It has passed the leakage current testing, which means that it has no power flows to the ground terminal. The product generates little noise during operation

ECOPURA 5gallon bottle washing filling capping machine HSG1200 with capacity 1200bph.

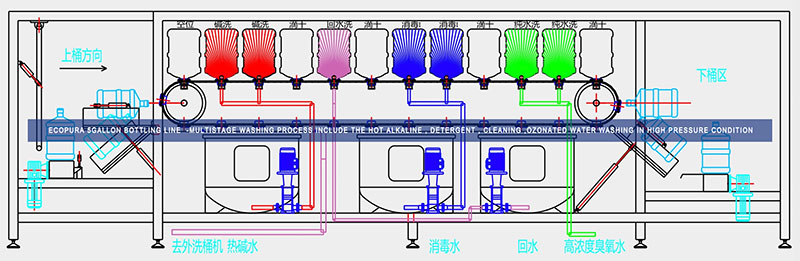

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

Bottles Sterilizing & Washing

Exclude the brusher pre-washing process for cleaning bottles inside & outside part, the pre-washed 5gallon bottles feed into the 3-in-1 washing filling capping unit which Designed Multistage high-pressure inner washing Process include Hot Alkaline washing, disinfection water washing, Dripping ,Ozonated pure water cleaning for ensuring the recycled bottles 100% clean & health, the washing system is controlled by pumping though cleaning tank and the ejecting nozzles on the bottle carrier to spraying the inner wall of the bottles by high pressure water, after finishing the washing process, the bottles will discharge though reverse turn-over mechanize and transported to the filling Part for full filling as designated volume and finally capping, discharge out the 3-in-1 by conveyor to next step

Caps Loading & washing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing

Rotary Filling & Capping

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Excellent in quality of bottle filling machine price , Shenzhen EcoPura Water Equipment Co.,Ltd has won customer's trust. Our products are popular all over the world. The export amount shows continuing good growth of our company and reflects the evolution of our business.

2. Our company is backed by a dedicated R&D team. They have years of extensive expertise in the manufacturing industry and are able to quickly develop new products according to the newest market trend.

3. Over the years of development, our company has established good strategic partnerships with clients all over the world. This is mainly because we have been providing excellent quality products and professional services. Shenzhen EcoPura Water Equipment Co.,Ltd keeps the mission of providing the best quality of Shenzhen EcoPura Water Equipment Co.,Ltd. Inquiry!