Company Advantages1. EcoPura beverage filling machine has passed defects checks. These inspections include scratches, cracks, broken edges, chip edges, pinholes, swirl marks, repairs, etc.

2. This product has premium quality and rich functionality.

3. As the stringent quality tests run through the whole production process, the quality of the product can be thoroughly assured.

4. Employing this product with the latest technology will allow manufacturers to complete work and projects with minimal quality defects.

5. The product is highly fuel-efficient. Thus, it helps in reducing CO2 considerably and help companies put their greener footprint forward.

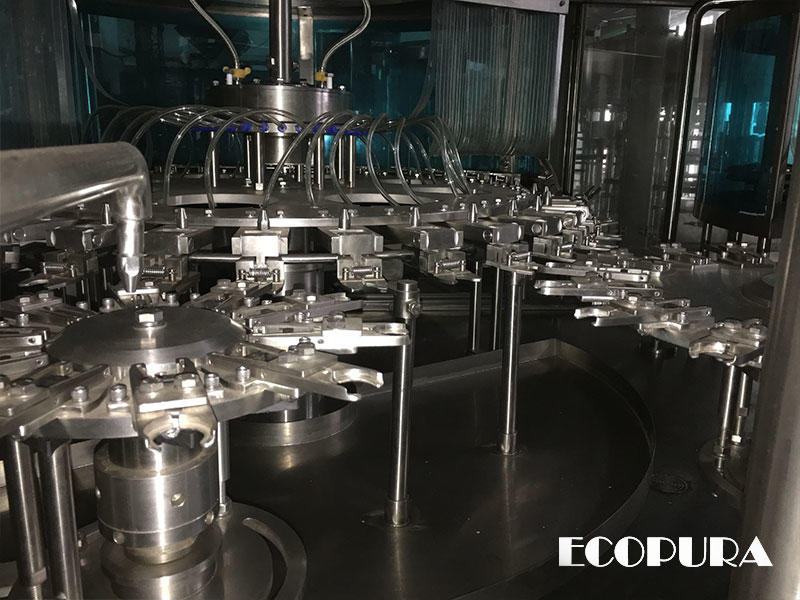

ECOPURA 4-in-1 PET 0.3L-1.5L DHSG-series monobloc equipped with isobaric filler nozzles designated for filling carbonated beverages such as Cola, beer, carbonated water and other liquids etc

Model |

Bottle Spec |

Capacity Cal@500ML | Power | PLC & HMI |

DHSG16-16-12-6 | 0.33L-1.5L

Height:150-330mm

Dia: 50-115mm |

3000-3500bph |

1.8kw | SIEMENS |

DHSG24-24-16-6 | 4000-5000bph | 2.2kw |

DHSG24-24-18-8 | 5000-6000bph | 2.2kw |

DHSG24-24-24-8 | 8000-9000bph | 3.0kw |

DHSG32-32-32-12 | 10000-12000bph | 5.5kw |

DHSG38-38-38-14 | 12000-15000bph | 7.5kw |

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. |

High quality & Strict Hygiene

Production of top-quality beverages requires conditions of strict hygiene, All parts that comes into contact with the beverage are manufactured in Stainless steel 304 or 316 Contactless filling

SIEMENS PLC & Touch Screen control with Integrated and separate electro-pneumatic components

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Ozonated water Washing Part

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316

hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination

The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Filling Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene.

The PET container is first pressed on by the PET lifting unit and pressurised afterwards. Once the same pressure is in the ring bowl and the PET container, the filling valve will be opened and the filling process starts. The liquid is gently fed via a swirl insert into the bottle. Two different filling speeds guarantee optimum flow behaviour. A flow meter monitors the fed liquid quantity. Once the exact filling volume has been reached, the flow meter provides a signal and the valve closes electro pneumatically

Maximum flexibility − Filling of non-carbonated and carbonated products on one system Maximum filling accuracy − Precise determination of fill quantity via inductive flow meter Gentle product treatment during filling − Low-foam and low-turbulence filling vias wirl insert in the valve

Hygiene and stable filling processes − Separate gas channels for pressurization and snifting

ECOPURA filling machines in their standard version are suitable for CIP and beverage mixer

Capping Part

The capper is most precise part ensuring the machine to run credibility and product quality.

The capping head applies the cap. The cap is pressed onto the bottle by means of spring pressure. At the same time it is screwed onto the thread of the bottle neck finish. As soon as the rotation is ended and the required tightening torque is applied to the cap, a hysteresis clutch ends the capping process.

All main parts made of stainless steel AISI304

Pick station with adjustable height

Torque and spring force of the capping head are adjustable

Flushable cap retainer

Motorised height adjustment of the capper top part with bottle selection feature

Caps online Sterilization

ECOPURA dedicated in every process details to control the hygiene such as for the caps sterilizing to ensure the maximum hygiene for your all kinds beverages. Caps online sterilizer made of stainless steel 316L with built in spraying device for high pressure Ozonated pure water sterilizing

Based in China, Shenzhen EcoPura Water Equipment Co.,Ltd is a leading manufacturer and supplier of a commendable range of products including beverage filling machine .

2. Shenzhen EcoPura Water Equipment Co.,Ltd adheres to the principle of 'satisfying customers'.

3. We aim to provide customers with the best, and only the best. Our passion for our brand and making it visible is the reason our customers trust us. Inquiry! We are ready to provide high quality soda filling machine price. Inquiry! Every stage of our operations presents an opportunity to eliminate waste. We have been focused on finding ways to reduce, reuse or recycle to divert waste from landfills. Inquiry! We are committed to fostering a sustainable development along our entire value chain in line with our economic, environmental and social responsibilities toward current and future generations.