Company Advantages1. EcoPura wine bottling line is designed after testing on the potential customers and the market research groups.

2. What distinguishes the product from others is the reliable quality, stable performance, and long service life.

3. The product raises the overall production in the economy. If used in industries, it will increase the productivity of all factors of production like land, labor, capital, etc.

4. The product is easily installed and comes with a complete detailed operation guide including user instructions, maintenance, and installation procedures.

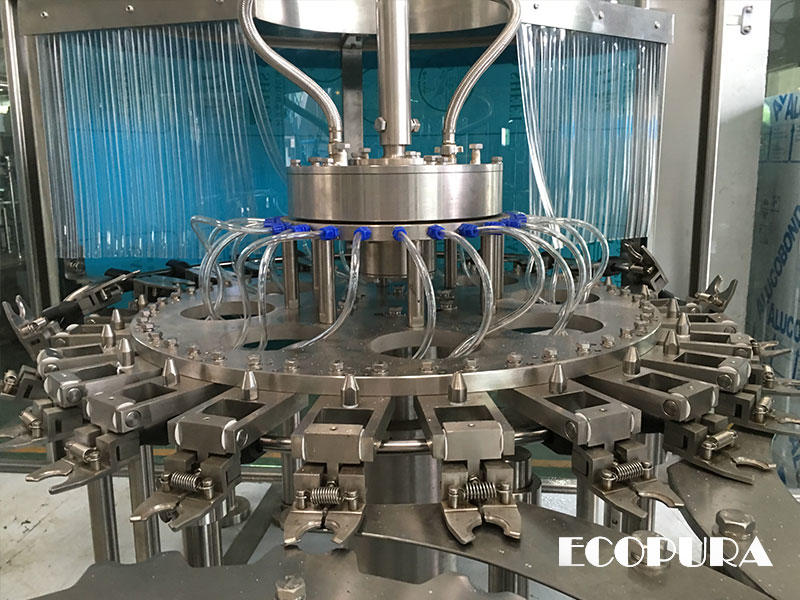

ECOPURA 3-in-1 Glass 0.3L-1.5L HSG-G series monobloc equipped with overflow filler nozzles designated for filling wine or Sparking wine

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

HSG8-8-3G | 0.33L-1.5L

Height:150-330mm

Dia: 50-115mm | 5000-3000bph | 1.5kw | SIEMENS |

HSG16-12-6G | 3000-4500bph |

1.8kw |

HSG24-16-6G | 5000-6000bph |

2.2kw |

HSG24-18-8G | 7000-8000bph |

2.2kw |

HSG24-24-8G | 10000-12000bph | 3.0kw |

HSG32-32-12G | 15000-18000bph | 5.5kw |

HSG38-38-14G | 18000-20000bph | 7.5kw |

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. |

High quality & Strict Hygiene

Production of top-quality beverages requires conditions of strict hygiene, All parts that comes into contact with the beverage are manufactured in Stainless steel 304 or 316

Contactless filling

SIEMENS PLC & Touch Screen control with Integrated and separate electro-pneumatic components

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316

hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination

The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Filling Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene.

The lift cylinder presses the bottle on to the filling valve where it is pre-evacuated several times. With non-carbonated beverages, the filling valve opens due to a movement of the control cylinder. With carbonated beverages, the bottle is pressurised and the valve opens as soon as the bottle and the ring bowl have the same pressure. At both of the filling processes, the liquid runs through a spreader along the bottle wall. The valve closes as soon as the bottle is entirely filled. The correction channel opens and the excessive fill quantity is displaced from the bottle to the end of the vent tube. With carbonated beverages, a snifting phase is performed in order to reduce the pressure in the bottle head space. Non- carbonated beverages can be removed from the filling valve right after filling is completed.

Aluminum Roll-On Capping Part

After they have been sorted according to their positions in the sorter, the caps are fed to the capper via an open chute. A towing shoe positions the caps, which are then directly picked up by the bottle. If a cap is missing, a safety plunger prevents contact between the rollers and the bottle neck finish. Depending on the cap type, a “fixed” or a deep-drawing plunger is used for press-on and shaping. The thread is rolled out via moveable arms, and if necessary, the tamper-evident band is flanged. The lateral pressure can be easily readjusted with adjusting screws.

Caps online Sterilization

ECOPURA dedicated in every process details to control the hygiene such as for the caps sterilizing to ensure the maximum hygiene for your all kinds beverages. Caps online sterilizer made of stainless steel 316L with built in spraying device for high pressure Ozonated pure water sterilizing

Shenzhen EcoPura Water Equipment Co.,Ltd is one of the most successful manufacturers of wine bottling equipment in the premium segment.

2. We have opened up and consolidated overseas sales channels. So far, we have accumulated our own loyal customer base in which customers are mainly from North America and Southeast Asia.

3. Shenzhen EcoPura Water Equipment Co.,Ltd always worked hard to provide quality services. Please contact us! By strictly following wine bottling line , Shenzhen EcoPura Water Equipment Co.,Ltd hopes to a world-class company in wine bottling machine industry. Please contact us! Enthusiastically participating in the task of serving customers and creating value is important for EcoPura in the future. Please contact us! Our vision is to become the dominant and well-known wine filling machine supplier domestically and abroad. Please contact us!