Company Advantages1. Such design of beer filler could potentially revolutionize beer bottle filling machine industry. The product is energy-saving, consuming little energy

2. Thanks to its fully advanced operation system, the product effectively cuts down the labor costs as there are fewer workers involved. The product has the advantage of low failure rate

3. The main functions of beer bottle filling machine are beer filler. Made of stainless steel materials, the product has a smooth surface to resist dust and dirt

4. beer bottle filling machine is designed to provide beer filler features over a long service life. The product is widely used for commercial applications

5. beer bottle filling machine firstly satisfy consumer demand for beer filler. The product is easy to clean with no blind corners

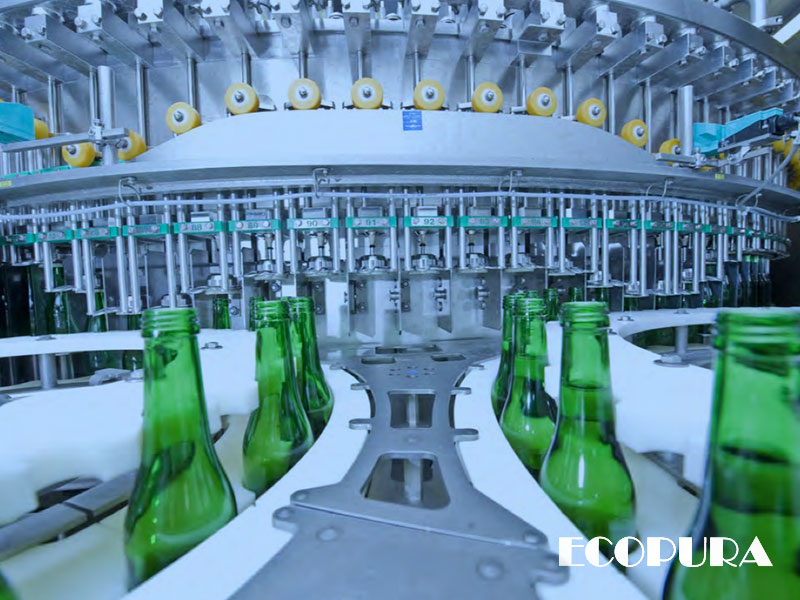

ECOPURA 3-in-1 Glass 0.3L-1.0L HSG-B series monobloc equipped with overflow filler nozzles designated for filling wine or Sparking wine

Model |

Bottle Spec |

Capacity Cal@500ML | Power | PLC & HMI |

HSG8-8-3G | 0.33L-1.5L

Height:150-330mm

Dia: 50-115mm |

2000-3000bph |

1.5kw | SIEMENS |

HSG16-12-6G |

3000-4500bph | 1.8kw |

HSG24-16-6G |

5000-6000bph | 2.2kw |

HSG24-18-8G |

7000-8000bph | 2.2kw |

HSG24-24-8G |

10000-12000bph | 3.0kw |

HSG32-32-12G |

15000-18000bph | 5.5kw |

HSG38-38-14G |

18000-20000bph | 7.5kw |

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. |

High quality & Strict Hygiene

Production of top-quality beverages requires conditions of strict hygiene, All parts that comes into contact with the beverage are manufactured in Stainless steel 304 or 316

Contactless filling

SIEMENS PLC & Touch Screen control with Integrated and separate electro-pneumatic components

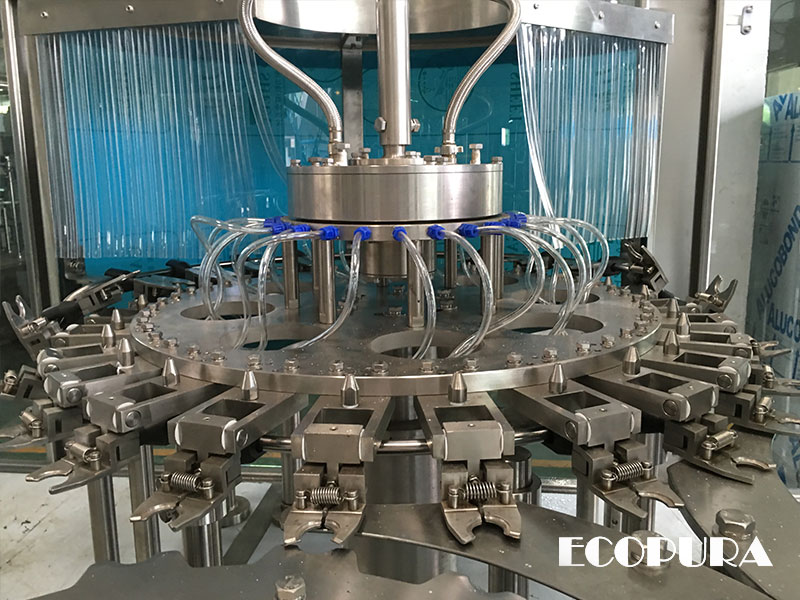

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316. hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Filling Part

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination

The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Crown Cappe

Once the crown has been fed from the crown chute into the transfer segment, a magnet is used for the further guidance of the crown. A pushing notch is then used to position the crown on the ejection plunger of the capping head. The crowning head is lowered until the crown in the crowning throat is placed on the bottle. The bottle then holds it in place. Afterwards only the crowning throat continues to be lowered. In the first phase, only the force of the guiding springs has any effect on the crown.

Caps online Sterilization

ECOPURA dedicated in every process details to control the hygiene such as for the caps sterilizing to ensure the maximum hygiene for your all kinds beverages. Caps online sterilizer made of stainless steel 316L with built in spraying device for high pressure Ozonated pure water sterilizing

Shenzhen EcoPura Water Equipment Co.,Ltd has become the core competitiveness among suppliers who manufacture beer filler. So far, we have achieved great accomplishment in manufacturing and developing of the products.

2. Apart from its delicate appearance, beer bottle filling machine also attracts many customers for its beer canning machine for sale .

3. With rich experience and mature technical products, Shenzhen EcoPura Water Equipment Co.,Ltd enjoys a high reputation in the domestic and foreign markets.