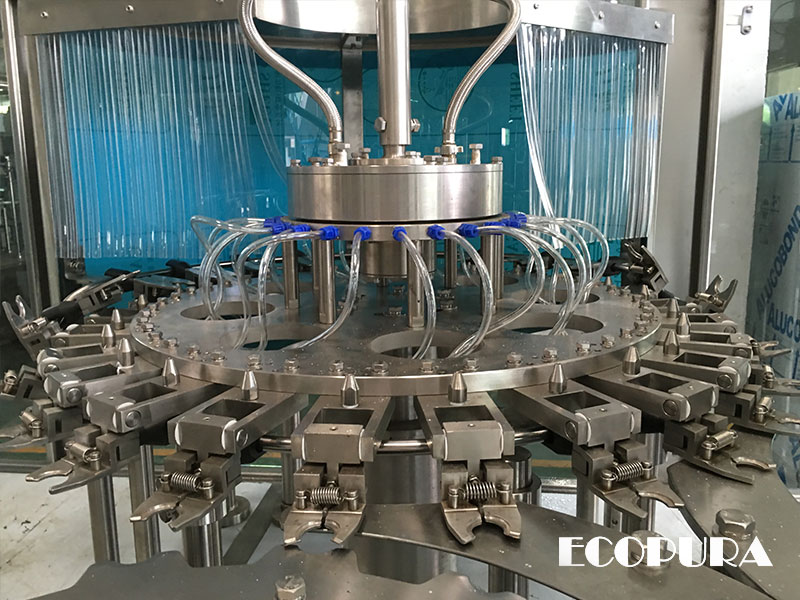

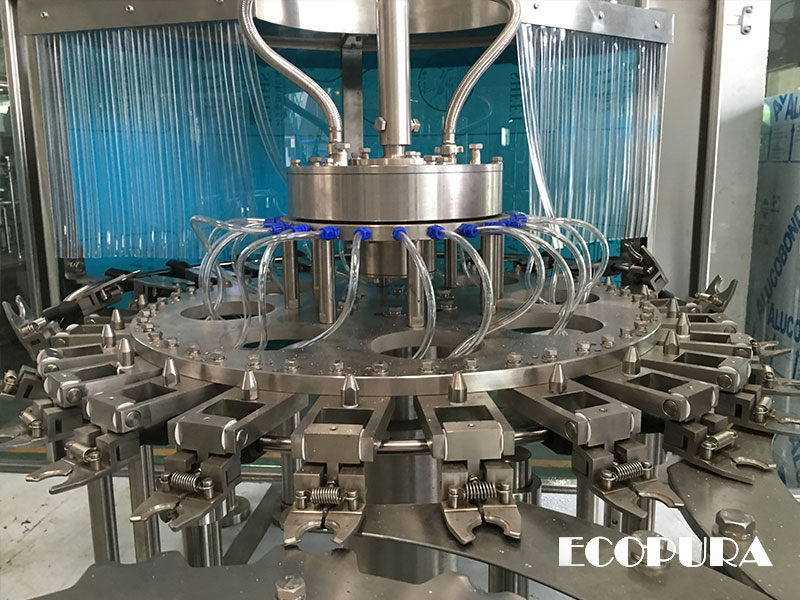

ECOPURA 4-in-1 PET 0.3L-1.5L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral ,still water and other liquids etc

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

HSG24-24-16-6 | 0.33L-1.5L | 5000-6000bph | 2.2kw | SIEMENS |

HSG24-24-18-8 | 7000-8000bph | 2.2kw | ||

HSG24-24-24-8 | 10000-12000bph | 3.0kw | ||

HSG32-32-32-12 | 15000-18000bph | 5.5kw | ||

HSG38-38-38-14 | 18000-20000bph | 7.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Why 4-in-1 ?

Twin bottle rinsing station include chemical water rinsing and Ozonated water rinsing ensuring the performance with strict hygiene standard

Chemical Washing Part

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.