ECOPURA 3-in-1 PET 0.3L-1.5L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral ,still water and other liquids etc

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

HSG8-8-3 | 0.33L-1.5L | 2000-3000bph | 1.5kw | SIEMENS |

HSG16-12-6 | 3000-4500bph | 1.8kw | ||

HSG24-16-6 | 5000-6000bph | 2.2kw | ||

HSG24-18-8 | 7000-8000bph | 2.2kw | ||

HSG24-24-8 | 10000-12000bph | 3.0kw | ||

HSG32-32-12 | 15000-18000bph | 5.5kw | ||

HSG38-38-14 | 18000-20000bph | 7.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

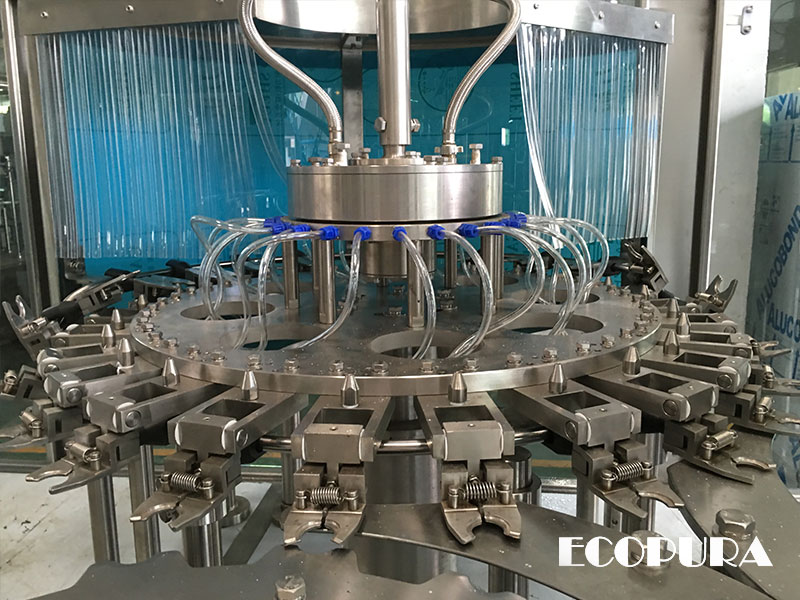

Washing Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene. Neck-handling grippers position the PET container beneath the filling valve. Once the container has been centred, the filling process starts: Thereby, the Filling valve is opened and the product flows into the bottle with infinitely variable speed. Once the required fill volume has been reached, the flow meter provides a signal to the filling valve. The valve is now closed and the filling process completed. Dripping of the filling valve is prevented by a sieve in the product discharge. Microbiological safety -Contact-free filling and optimized machine design. High filling accuracy -Use of flow meters and infinitely variable flow speeds High availability -Top efficiency thanks to the combination with ECOPURA cap feed systems .ECOPURA standard Machines are suitable for CIP

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.