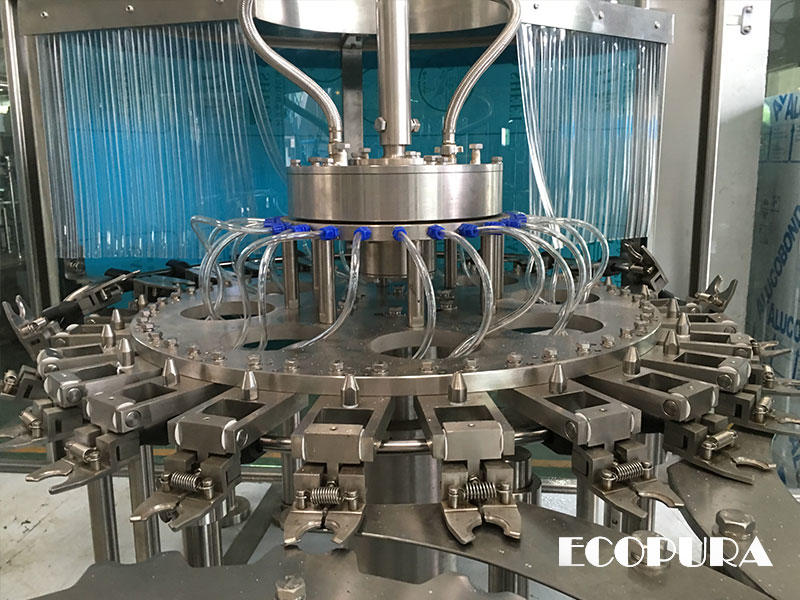

ECOPURA 3-in-1 PET 0.3L-1.5L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral ,still water and other liquids etc

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

HSG8-8-3 | 0.33L-1.5L | 2000-3000bph | 1.5kw | SIEMENS |

HSG16-12-6 | 3000-4500bph | 1.8kw | ||

HSG24-16-6 | 5000-6000bph | 2.2kw | ||

HSG24-18-8 | 7000-8000bph | 2.2kw | ||

HSG24-24-8 | 10000-12000bph | 3.0kw | ||

HSG32-32-12 | 15000-18000bph | 5.5kw | ||

HSG38-38-14 | 18000-20000bph | 7.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Washing Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene. Neck-handling grippers position the PET container beneath the filling valve. Once the container has been centred, the filling process starts: Thereby, the Filling valve is opened and the product flows into the bottle with infinitely variable speed. Once the required fill volume has been reached, the flow meter provides a signal to the filling valve. The valve is now closed and the filling process completed. Dripping of the filling valve is prevented by a sieve in the product discharge. Microbiological safety -Contact-free filling and optimized machine design. High filling accuracy -Use of flow meters and infinitely variable flow speeds High availability -Top efficiency thanks to the combination with ECOPURA cap feed systems .ECOPURA standard Machines are suitable for CIP

PET Bottle Carbonated Soft Drink Filler for Sale

Carbonated Soft Drink Filler --- Features

(1)This carbonated soft drink filler is a unique design combining the three machines of bottle washing, filling and capping in one to decrease main power, to save space and to diminish the air pollution among the three machines.

(2) The carbonated soft drink filler is applicable for carbonated drink filled in plastic bottles and capped with plastic caps, with optional capacity from 1200BPH to 12000BPH.

(3) The carbonated soft drink filler is easy to change the shape of bottles, which can be done by changing the thumb wheel without adjusting the height of the machine.

(4) The machine adopts suspensory transmission gear, which can easily upkeep and be repaired.

(5) This carbonated soft drink filler's case and the parts contacting with the materials are made of stainless steel which ensures the good external look and easy washing.

(6) The carbonated soft drink filler uses frequency changer to control the main machine motor. And it has an output number indicating function which is easy to control the adjustment of the output.

(7) Human-machine interface touch-screen is adopted in the beverage filling machine. The liquid level in the tank can be controlled automatically. The filling and capping will stop automatically when there is not bottle.

(8) The carbonated soft drink filler has constant temperature circle system , temperature and circumfluence are controlled automatically.

PET Bottle Carbonated Soft Drink Filler for Sale

Carbonated Soft Drink Filler --- Technical Parameters

Model | CGFD8-8-3 | CGFD16-12-6 | CGFD18-18-6 | CGFD24-24-8 | CGFD32-32-10 | CGFD40-40-10 |

Washing No | 8 | 16 | 18 | 24 | 32 | 40 |

Filling No | 8 | 12 | 18 | 24 | 32 | 40 |

Capping No | 3 | 6 | 6 | 8 | 10 | 10 |

Production capacity(500ml b/h) | 1200-1500 | 2500 | 3500-4000 | 7000-7500 | 8000-10000 | 10000 |

Installed Capacity(kw) | 3 | 3.5 | 4 | 4.8 | 7.6 | 8.3 |

Overall size | 2250*1800*2400 | 2450*1800*2400 | 2650*1900*2400 | 2900*2100*2400 | 4100*2400*2400 | 4550*2650*2400 |

PET Bottle Carbonated Soft Drink Filler for Sale

PET Bottle Carbonated Soft Drink Filler for Sale

What service U Tech Machine Co.,Ltd can offer you ?

• Well-trained & experienced staff are to answer all your inquiries in English and Chinese

• 24 hours for engineer response (all services part 5days in customer hand by Intl' courier).

• 2 Years guarantee

• Your business relationship with us will be confidential to any third party.

• Good after-sale service offered, please get back to us if you got any questions.

PET Bottle Carbonated Soft Drink Filler for Sale

company introduction

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment.

Our products include: liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc.), barreled filling line (3-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC...) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

our factory

Certification

Exhibition in Colombia

PET Bottle Carbonated Soft Drink Filler for Sale

Q1:Are you a trading company or a manufactory?

A1:We are a manufactory,can give u best service .

Q2:What’s your guarantee or the warranty of the quality if we buy your machines?

A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.

Welcome To Visit Zhangjiagang U Tech Machine Co.,Ltd!

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.