Company Advantages1. EcoPura beer filler is developed in line with international safety standards for electrical equipment. It is guaranteed by these standards to run safely. The product is energy-saving, consuming little energy

2. We value this product for the speed with which it works, and in the modern world, speed matters the most. - Said one of our customers. The product can enhance the speed, accuracy, and efficiency of workers

3. The product can be stored for a long time. The ingredients contained in it are less prone to oxidization and deterioration. The product is easy to clean with no blind corners

4. The product is of high quality. It has the perfect craftsmanship of the hardware, inner lining, the seams, and the stitching. The product generates little noise during operation

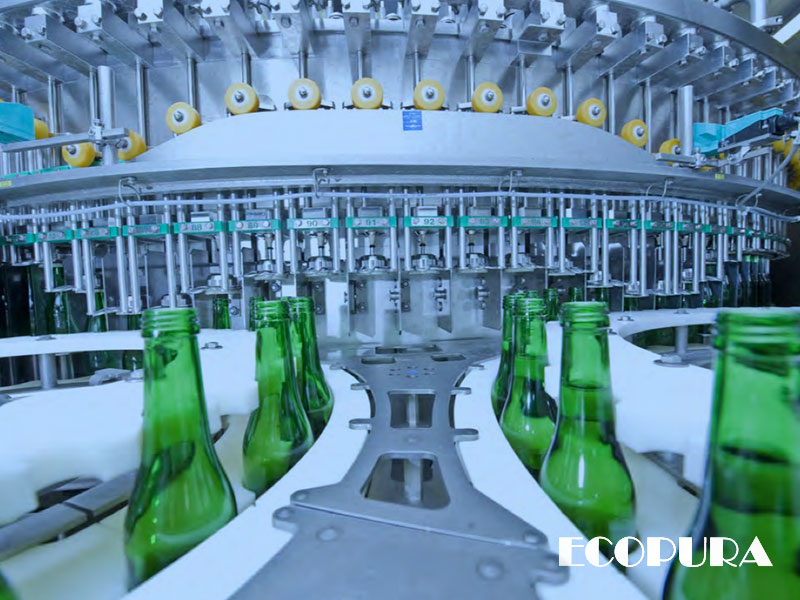

ECOPURA 3-in-1 Glass 0.3L-1.0L HSG-B series monobloc equipped with overflow filler nozzles designated for filling wine or Sparking wine

Model |

Bottle Spec |

Capacity Cal@500ML | Power | PLC & HMI |

HSG8-8-3G | 0.33L-1.5L

Height:150-330mm

Dia: 50-115mm |

2000-3000bph |

1.5kw | SIEMENS |

HSG16-12-6G |

3000-4500bph | 1.8kw |

HSG24-16-6G |

5000-6000bph | 2.2kw |

HSG24-18-8G |

7000-8000bph | 2.2kw |

HSG24-24-8G |

10000-12000bph | 3.0kw |

HSG32-32-12G |

15000-18000bph | 5.5kw |

HSG38-38-14G |

18000-20000bph | 7.5kw |

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. |

High quality & Strict Hygiene

Production of top-quality beverages requires conditions of strict hygiene, All parts that comes into contact with the beverage are manufactured in Stainless steel 304 or 316

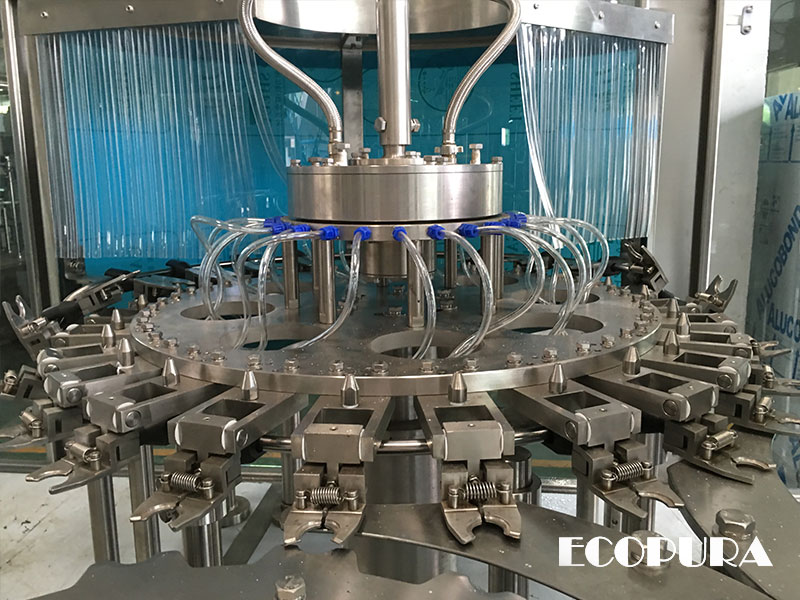

Contactless filling

SIEMENS PLC & Touch Screen control with Integrated and separate electro-pneumatic components

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316. hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Filling Part

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination

The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Crown Cappe

Once the crown has been fed from the crown chute into the transfer segment, a magnet is used for the further guidance of the crown. A pushing notch is then used to position the crown on the ejection plunger of the capping head. The crowning head is lowered until the crown in the crowning throat is placed on the bottle. The bottle then holds it in place. Afterwards only the crowning throat continues to be lowered. In the first phase, only the force of the guiding springs has any effect on the crown.

Caps online Sterilization

ECOPURA dedicated in every process details to control the hygiene such as for the caps sterilizing to ensure the maximum hygiene for your all kinds beverages. Caps online sterilizer made of stainless steel 316L with built in spraying device for high pressure Ozonated pure water sterilizing

With cutting-edge technology and professional staff equipped, EcoPura is proud to be the leading beer bottle filling machine supplier. Our production capacity occupies steadily in the forefront of the beer filling machine industry.

2. All our technical staff are rich in experience for beer bottling machine .

3. Our Shenzhen EcoPura Water Equipment Co.,Ltd has already passed relative audit. We concern local education and culture development. We have subsidized many students, donated educational finance to schools in poor areas and to some cultural centers and libraries.