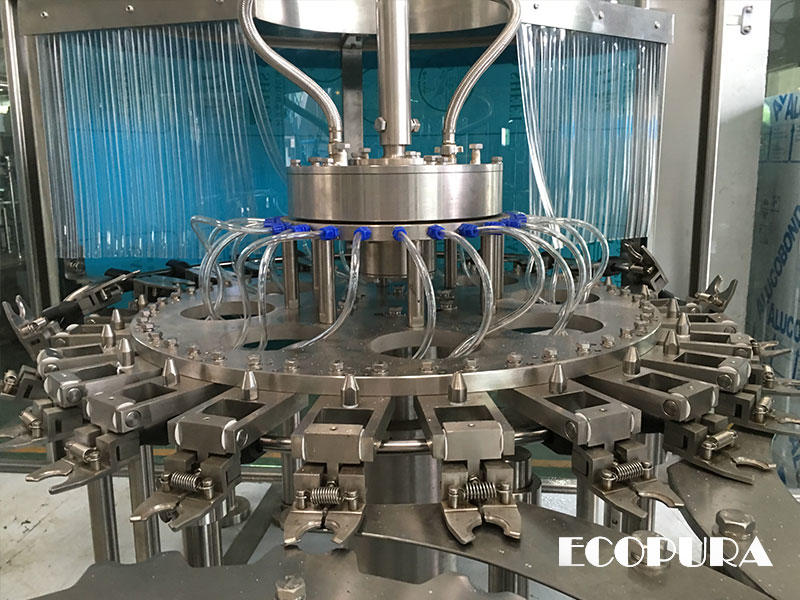

ECOPURA 3-in-1 PET 0.3L-1.5L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral ,still water and other liquids etc

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

HSG8-8-3 | 0.33L-1.5L | 2000-3000bph | 1.5kw | SIEMENS |

HSG16-12-6 | 3000-4500bph | 1.8kw | ||

HSG24-16-6 | 5000-6000bph | 2.2kw | ||

HSG24-18-8 | 7000-8000bph | 2.2kw | ||

HSG24-24-8 | 10000-12000bph | 3.0kw | ||

HSG32-32-12 | 15000-18000bph | 5.5kw | ||

HSG38-38-14 | 18000-20000bph | 7.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Washing Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene. Neck-handling grippers position the PET container beneath the filling valve. Once the container has been centred, the filling process starts: Thereby, the Filling valve is opened and the product flows into the bottle with infinitely variable speed. Once the required fill volume has been reached, the flow meter provides a signal to the filling valve. The valve is now closed and the filling process completed. Dripping of the filling valve is prevented by a sieve in the product discharge. Microbiological safety -Contact-free filling and optimized machine design. High filling accuracy -Use of flow meters and infinitely variable flow speeds High availability -Top efficiency thanks to the combination with ECOPURA cap feed systems .ECOPURA standard Machines are suitable for CIP

1. Principal feature

Carbonated drink washing, filling, capping 3 in 1 machine combines the carbonate beverage bottle washing, filling, capping functions on one machine. The design of the machine is scientific and reasonable.The appearance is beautiful and the function is complete. Carbonated drink washing, filling, capping 3 in 1 machine is easy to operate and maintain.

High automation. Carbonated drink washing, filling, capping 3 in 1 machine is controlled by PLC with touchi-screen. The amount of the bottling can be controlled automatically. The working will be stopped automatically when there is no bottle. When bottles are cramped wrongly or when caps are not available, the machine can be stopped automatically.

Direct after-sales service

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.