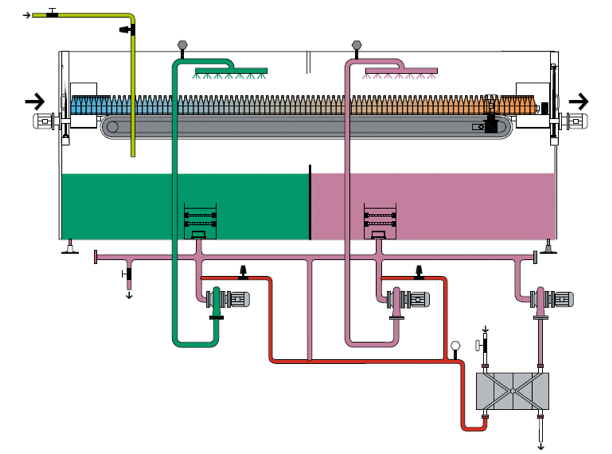

The tunnel cooler designated for adjusting the temperature of the Hot filled products to ambient temperature by cool spraying system and thereby ensuring that no distorting their taste or color,

♦ Spraying nozzle system for quick and defined bottle treatment

♦ Clean design in stainless steel AISI304

♦ Efficient cooling performance thanks to even water distribution and snap-in spraying system

♦ Controlled by SIEMENS PLC & HMI and Frequency controlled drive system

♦ Cooling of all products in glass bottles, PET containers and cans

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.