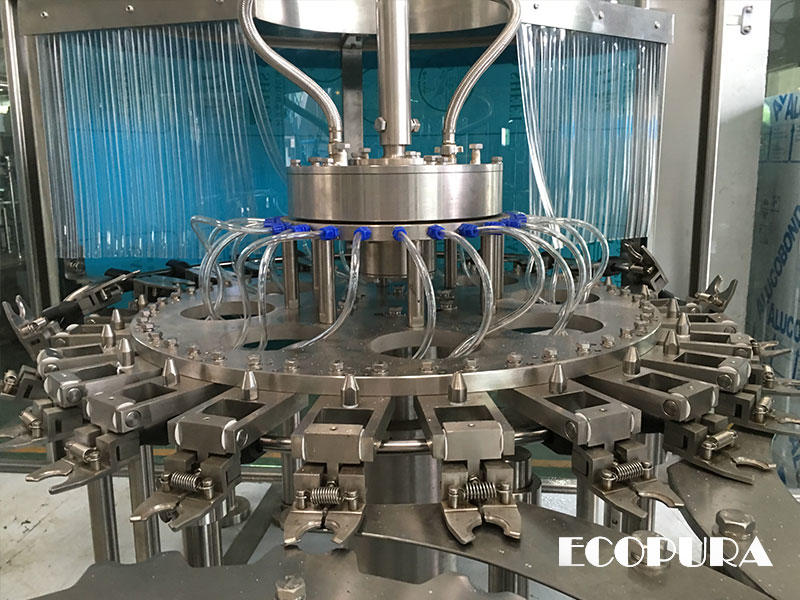

ECOPURA 3-in-1 PET 0.3L-1.5L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral ,still water and other liquids etc

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

HSG8-8-3 | 0.33L-1.5L | 2000-3000bph | 1.5kw | SIEMENS |

HSG16-12-6 | 3000-4500bph | 1.8kw | ||

HSG24-16-6 | 5000-6000bph | 2.2kw | ||

HSG24-18-8 | 7000-8000bph | 2.2kw | ||

HSG24-24-8 | 10000-12000bph | 3.0kw | ||

HSG32-32-12 | 15000-18000bph | 5.5kw | ||

HSG38-38-14 | 18000-20000bph | 7.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Washing Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene. Neck-handling grippers position the PET container beneath the filling valve. Once the container has been centred, the filling process starts: Thereby, the Filling valve is opened and the product flows into the bottle with infinitely variable speed. Once the required fill volume has been reached, the flow meter provides a signal to the filling valve. The valve is now closed and the filling process completed. Dripping of the filling valve is prevented by a sieve in the product discharge. Microbiological safety -Contact-free filling and optimized machine design. High filling accuracy -Use of flow meters and infinitely variable flow speeds High availability -Top efficiency thanks to the combination with ECOPURA cap feed systems .ECOPURA standard Machines are suitable for CIP

1. Are you the factory?

Yes. Our company engaged in packing machinery for ten years.

2. Can you do customized packing machine?

Yes,of course. We are specific packing machinery manufacturer with morn than 10 years experiences,we can do packing machinery accourding to the customer's requirements.

3. I there any installation direction after we received the machine?

Yes, we have a professional technical team and warm after service. We will solve any problem you meet during the installation and packing production in time.

4. Is there any ensurance to guarantee my order from your company?

We are an onsite check factory from Alibaba, and the quality, delivery time, your payment are all ensured by Alibaba trade assurance. If you have any question please don't hesitate to contact us, we will give you a warm and rapid reply.

Model No: XT-DPA-FL

All of our machine can be customized

The packing line is include bottle unscramble——bottle filling and capping machine——labeling machine(printer)——carton machine(optional)——film packing machine——collecting plate.high-intellection filling line only one operator and three assistant worker can control the whole line.

Product Characteristics

Technical Parameters

| Model | XT-DPA-FL |

| Packing Speed(pcs/min) | 4000BPH (Customized) |

| Packing Accuracy | ± 0.5 % |

| Filling Nozzles | 1-6 head(follow customer requirement) |

| Bottle Type | Plastic/Glass bottles/cans/jars/tubes etc |

| Cap Type | Plastic srew cap/Aluminium caps etc |

| Power Supply | AC220V 50/60HZ 1500W |

Detail Picture

Configuration(Optional for other Europe Brand)

| Item | Name | Configurarion | |

| 1 | Machine Frame | SS 304 & SS316 | |

| 2 | Protection Cover | PC Material | |

| 3 | HMI | Siemens | Germany |

| 4 | PLC | Siemens | Germany |

| 5 | Filling Valve | FESTO | Germany |

| 6 | Coupling Hose (FDA) | Goodyear | America |

| 7 | Pneumatic element | Airtac | Taiwan |

| 8 | Servo System | Siemens | Germany |

| 9 | AC Motor | ABB | Switzerland |

| 10 | Electric element | Schneider Omron | France Japan |

| 11 | Photoelectric Sensor | Sick | Germany |

| Item | Name | Brand | Origin Country |

| 1 | PLC | Siemens | Germany |

| 2 | HMI | Siemens | Germany |

| 3 | Label Sensor | Schneider | France |

| 4 | Switch | Schneider | France |

| 5 | Servo Label Feeding | Schneider | France |

| 6 | Driver | Schneider | France |

| 7 | Main Motor | Siemens | Germany |

| 8 | Conveyor | Siemens | Germany |

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.