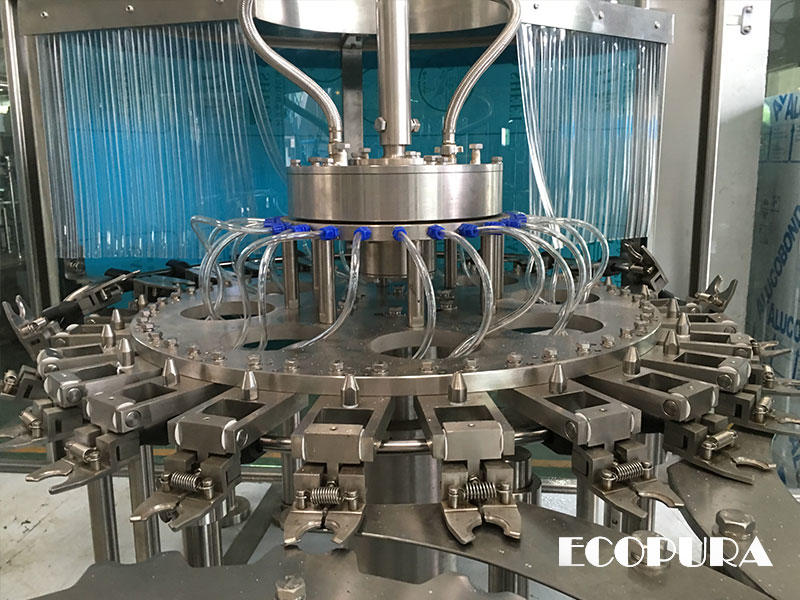

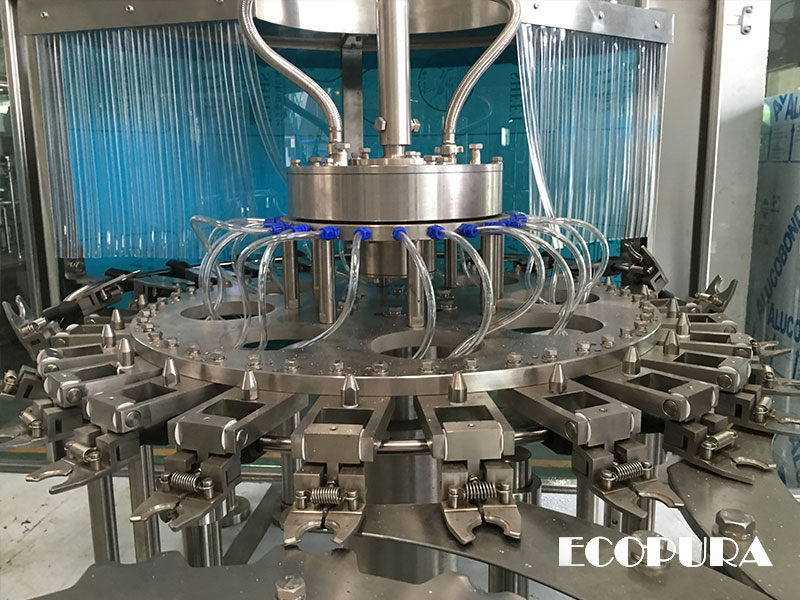

ECOPURA 4-in-1 PET 0.3L-1.5L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral ,still water and other liquids etc

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

HSG24-24-16-6 | 0.33L-1.5L | 5000-6000bph | 2.2kw | SIEMENS |

HSG24-24-18-8 | 7000-8000bph | 2.2kw | ||

HSG24-24-24-8 | 10000-12000bph | 3.0kw | ||

HSG32-32-32-12 | 15000-18000bph | 5.5kw | ||

HSG38-38-38-14 | 18000-20000bph | 7.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Why 4-in-1 ?

Twin bottle rinsing station include chemical water rinsing and Ozonated water rinsing ensuring the performance with strict hygiene standard

Chemical Washing Part

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Small negative pressure carbonated soft drink fillingmachine/ fruit juice bottle filler/ beer wine bottling

NO.1 Automatic Level Filling Machine

This machine is applicable to wine ,white wine,juice,rice wine,soy sauce and vinegar,which can finish bottle filling with same level automatically.

♦ Low vacuum filling: avoid the foaming and leaking; and if there is defects in the bottle, filling will not be started

♦ Spraying filling: Liquid flows down along the sides of the bottles to ensure the filling quality

♦ No bottle broken: bottle holding devices can flexibly adjust bottle location, avoiding any possible bottle damage or even machine damage

♦ Long service life and easy maintenance

| Model | GFGFP - 36 |

| Production capacity | (500ml/b/h) 10000 |

| Number of filling head | 36 |

| Bottle height | 150-320(mm) (subject to the bottle type provided by the customer) |

| Powe | 3 (KW) |

| Dimensions | 2500×2350×2200 (subject to actual equipment) |

Filling Valve Details NO.2

Product performance

♦ It has 36 filling valves

♦ The filling level is same with each bottle

Model | Head number | Capability (b/h) | Filling level accuracy (mm) | Power (KW) | Dimensions (mm) |

GFGFP-12 | 12 | 3000 | ±1.5mm | 1.12 | 1045×985×2200 |

GFGFP-18 | 18 | 4500 | ±1.5mm | 1.12 | 1500×1600×2200 |

GFGFP-24 | 24 | 6000 | ±1.5mm | 1.85 | 1900×1900×2200 |

GFGFP-30 | 30 | 8000 | ±1.5mm | 2.5 | 2100×2170×2200 |

GFGFP-36 | 36 | 10000 | ±1.5mm | 3 | 2500×2350×2200 |

GFGFP-40 | 40 | 12000 | ±1.5mm | 3.7 | 2500×2500×2200 |

GFGFP-48 | 48 | 14000 | ±1.5mm | 6 | 2800×2900×2200 |

NO.3 Machine Details

Product Performance

♦ This drive plate can be changed when the bottle is different

♦ It can adjust the bottle with same space

Machine Details NO.4

Labeling Machine

♦ The manhole's setting is using for cleaning

♦ The liquidometer's setting can check the level of tank

INSTALL DEDUGGING

--------------------------------

SHIPPING & PACKING

♦ Logistics: All machines will be sent by Shipping Logistics or Air Logistics, if you need other kind of transportation, please inform us in advance.

♦ Delivery time: Shipped in 10-15 days after payment.

About us

---------------------

Qingzhou Gofar Packaging Machinery Co., Ltd. is a professional manufacturer engaged in the research, development, production, sale and service of Bottle washing machine; Filling machine; Sealing machine; Labeling machine; Water treatment machine.

The company was established in 2012 years, has many enterprises at home and abroad to establish a long- term friendly business relationship.Prior to this, we have been engaged in the packaging equipment industry for more than 20 years.

We are located in Weifang, Shandong Province, China. It is very near to QingDao Port.With convenient transportation access. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.

In recent years, our company has introduced a series of equipment including laser cutting machine, C N C tapping machine, machining center.

more >>

why choose us

-----------------------

01 Over 25 year's production and sales experience of Packing Machine | 02 Every Part of Packing Line | 03 ISO 9001 |

04 OEM & ODM projects | 05 Convenient Transportation, | 06 The after-sales guarantee system provides you with at least |

Customer visiting

--------------------------------

PIC 1:The Ghana industrial association entered into a strategic partnership with our company.We will take part in the exhibition in the west africa.

PIC 2:The customer from Mongolia has signed a contract with our company for the production line of 5 gallons for drinking water, and has established a long-term cooperative relationship with our company.

PIC 3:The customers from South Korea visit the company and have dinner with the company leaders.

PIC 4:The customers from Iran came to our company to visit the production site of packaging equipment and gave high comments.

PIC 5:The after-sales team of the company takes a photo after finishing the work on the customer site.

PIC 6:The company's business manager poses with tanzanian customers

Packaging:

First Rust inhibitor;

Second Wrap film;

Third Plywood cases;

Last in container.

Also you can got all photos from coffee.

Shipping:

First contact you the machine is ok.

Second put the freight come and take the machine.

Receiving.

Accept!

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.