Company Advantages1. The design of EcoPura water plant machine price is created with care. It is defined as the use of imagination, scientific principles, and engineering techniques. Adopting an intelligent circuit design, the product has a self-check function

2. Some of our customers say it is especially comfortable to wear in the hot summer because their feet will not generate too much sweat and odors. Adopting an advanced touch screen, it is easy to use

3. It brings remarkable color effects. The color of the final produced garment would be exactly the same as the sample shown, and the accessories are also of the right color. The product features excellent torque accuracy

4. This product is characterized by good air circulation between the skin surface and the environment. Good ventilation at skin level and the possibility of eliminating the excess humidity generated through perspiration. The product features a high degree of automation

5. The product is sustainable. It is made of recyclable parts which are environmentally friendly and these parts can stand up many times of use. It has a robust design, supported by an aluminum plate

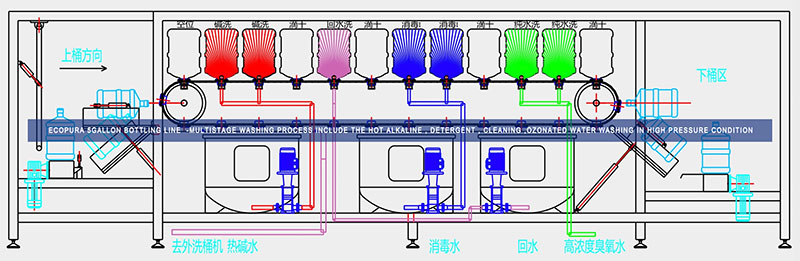

ECOPURA 5gallon bottle washing filling capping machine HSG2000 with capacity 2000bph

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

Bottles Sterilizing & Washing

Exclude the brusher pre-washing process for cleaning bottles inside & outside part, the pre-washed 5gallon bottles feed into the 3-in-1 washing filling capping unit which Designed Multistage high-pressure inner washing Process include Hot Alkaline washing, disinfection water washing, Dripping ,Ozonated pure water cleaning for ensuring the recycled bottles 100% clean & health, the washing system is controlled by pumping though cleaning tank and the ejecting nozzles on the bottle carrier to spraying the inner wall of the bottles by high pressure water, after finishing the washing process, the bottles will discharge though reverse turn-over mechanize and transported to the filling Part for full filling as designated volume and finally capping, discharge out the 3-in-1 by conveyor to next step

Caps Loading & washing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing

Rotary Filling & Capping

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Engaged in water filling equipment for many years, Shenzhen EcoPura Water Equipment Co.,Ltd has been a leading company. We have an excellent design team. It consists of experienced professionals who are creative and skillful to design customers' thoughts. They are able to turn the client’s imagination and vision into a successful project.

2. Thanks to our extensive marketing channels across the world, we have corporated with our many famous customers overseas and deliver them the best quality products.

3. Our manufacturing achievements have been recognized through a series of impressive awards. These awards are city advanced enterprises, county advanced enterprises and so on. We will embrace the principles of environmental sustainability across the board. We are making some tremendous efforts in going green by slashing our energy usage and supporting green energy projects.