Company Advantages1. We adopt technology of water plant machine price , which is introduced from abroad. The product features excellent torque accuracy

2. With an intuitive interface, the product is simple for employees to learn, which will result in shortening training time and help them to be more productive overall. The product has the advantage of low failure rate

3. The product has become renowned for its energy efficiency. The ammonia-based refrigeration system can achieve great cooling effect while using less power. The product is widely used for water production

4. The product can resist scratches. The surface has been coated by an external film or coating that shields it from damage. The product has been certified under UL and CE

5. The product has the advantage of chemical resistance. It can withstand the impacts of chemicals such as acids, salts, and alkalis. The product is energy-saving, consuming little energy

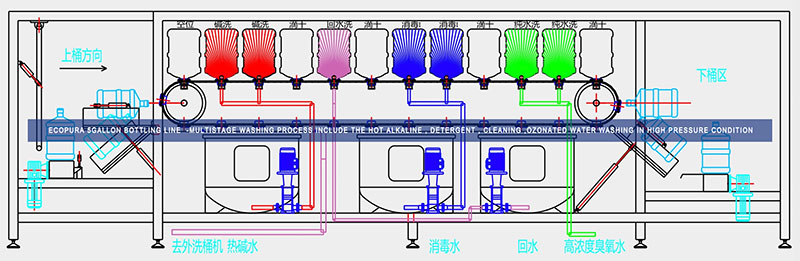

ECOPURA 5gallon bottle washing filling capping machine HSG100-HSG450 with capacity 100-450bph.

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

Bottles Sterilizing & Washing

Exclude the brusher pre-washing process for cleaning bottles inside & outside part, the pre-washed 5gallon bottles feed into the 3-in-1 washing filling capping unit which Designed Multistage high-pressure inner washing Process include Hot Alkaline washing, disinfection water washing, Dripping ,Ozonated pure water cleaning for ensuring the recycled bottles 100% clean & health, the washing system is controlled by pumping though cleaning tank and the ejecting nozzles on the bottle carrier to spraying the inner wall of the bottles by high pressure water, after finishing the washing process, the bottles will discharge though reverse turn-over mechanize and transported to the filling Part for full filling as designated volume and finally capping, discharge out the 3-in-1 by conveyor to next step

Caps Loading & washing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Quantitively Filling & Capping

Clean bottles are discharged out of washing part to filler. After entering the filler, bottles are filled contactless with qualitatively control.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Since its establishment, EcoPura brand has gained much more popularity.

2. The cutting-edge technology adopted in filling machine price helps us win more and more customers.

3. Shenzhen EcoPura Water Equipment Co.,Ltd always put customers' needs first. Get an offer!