Company Advantages1. The design of EcoPura soda filling machine price is the application of various disciplines. They include mathematics, kinematics, statics, dynamics, mechanical technology of metals and engineering drawing.

2. drink filling machine has basically comes up to the standards in terms of soda filling machine price.

3. The service life of product far exceeds the industry average.

4. This product can turn out thousands of identical outcomes. Production has thus been standardized. Only this kind of product is capable of mass production.

5. This product will remove the physical need of man, and created a society that has never been known to man.

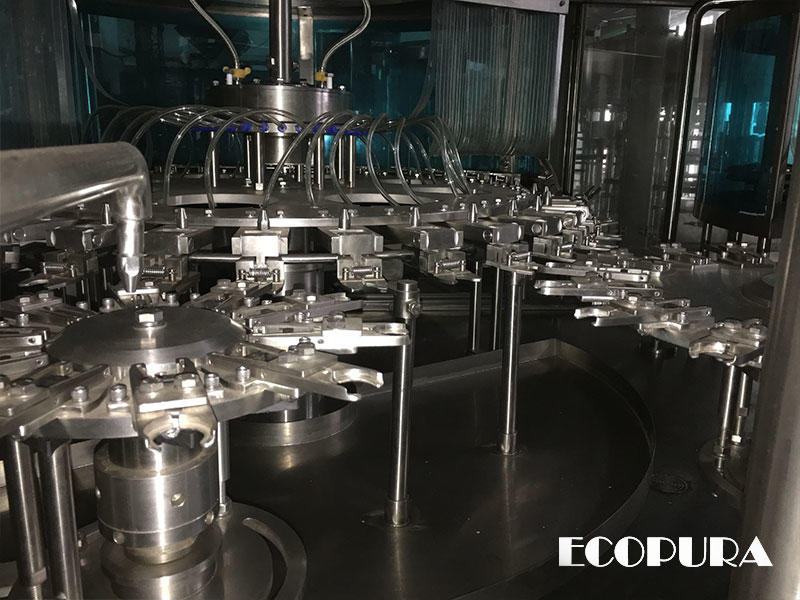

ECOPURA 3-in-1 PET 0.3L-1.5L DHSG-series monobloc equipped with isobaric filler nozzles designated for filling carbonated beverages such as Cola, beer, carbonated water and other liquids etc

Model |

Bottle Spec |

Capacity Cal@500ML | Power | PLC & HMI |

DHSG16-12-6 | 0.33L-1.5L

Height:150-330mm

Dia: 50-115mm |

3000-3500bph |

1.8kw | SIEMENS |

DHSG24-16-6 | 4000-5000bph | 2.2kw |

DHSG24-18-8 | 5000-6000bph | 2.2kw |

DHSG24-24-8 | 8000-9000bph | 3.0kw |

DHSG32-32-12 | 10000-12000bph | 5.5kw |

DHSG38-38-14 | 12000-15000bph | 7.5kw |

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. |

High quality & Strict Hygiene

Production of top-quality beverages requires conditions of strict hygiene, All parts that comes into contact with the beverage are manufactured in Stainless steel 304 or 316

Contactless filling

SIEMENS PLC & Touch Screen control with Integrated and separate electro-pneumatic components

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316. hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Filling Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene.The PET container is first pressed on by the PET lifting unit and pressurised afterwards. Once the same pressure is in the ring bowl and the PET container, the filling valve will be opened and the filling process starts. The liquid is gently fed via a swirl insert into the bottle. Two different filling speeds guarantee optimum flow behaviour. A flow meter monitors the fed liquid quantity. Once the exact filling volume has been reached, the flow meter provides a signal and the valve closes electro pneumatically Maximum flexibility − Filling of non-carbonated and carbonated products on one system Maximum filling accuracy − Precise determination of fill quantity via inductive flow meter Gentle product treatment during filling − Low-foam and low-turbulence filling vias wirl insert in the valve

Hygiene and stable filling processes − Separate gas channels for pressurization and snifting

ECOPURA filling machines in their standard version are suitable for CIP and beverage mixer

Capping Part

The capper is most precise part ensuring the machine to run credibility and product quality.

The capping head applies the cap. The cap is pressed onto the bottle by means of spring pressure. At the same time it is screwed onto the thread of the bottle neck finish. As soon as the rotation is ended and the required tightening torque is applied to the cap, a hysteresis clutch ends the capping process.

All main parts made of stainless steel AISI304

Pick station with adjustable height

Torque and spring force of the capping head are adjustable

Flushable cap retainer

Motorised height adjustment of the capper top part with bottle selection feature

Caps online Sterilization

ECOPURA dedicated in every process details to control the hygiene such as for the caps sterilizing to ensure the maximum hygiene for your all kinds beverages. Caps online sterilizer made of stainless steel 316L with built in spraying device for high pressure Ozonated pure water sterilizing

EcoPura has been vigorously developing modern drink filling machine industries such as soda filling machine price.

2. Our professional team members show their expertise in the design and manufacturing process. They highly excel in engineering, design, manufacturing, testing and quality control for years.

3. Our company bears social responsibility. We work with local energy providers that use green energy sources to generate power that is free of carbon emissions and other GHG. Our goal is to put our customers at the center of everything we do. We hope that our products and services are that our customers exactly need and that fit seamlessly into their business. Our firm bears societal responsibilities. We regularly monitor the air quality in our manufacturing plant to keep a check on the levels of harmful particulates and take corrective measures to reduce pollution. Our goal is to deliver the highest quality products and use our position in the value chain to contribute positively to our customers.