Company Advantages1. Every EcoPura tea filling machine is guaranteed by a series of processes including raw material extraction, accurate and rigorous prototyping and regular tests on physical and chemical properties.

2. The product has a smooth surface. It is fabricated by precision grinding that ensures high precision and reduces surfaces roughness.

3. The product features remarkable loading strength. Its materials, mainly metals, have desired mechanical properties to endure heavy-duty use.

4. Shenzhen EcoPura Water Equipment Co.,Ltd has a knowledgeable talent team and a stable and reliable production line.

5. Shenzhen EcoPura Water Equipment Co.,Ltd provides fast lead times for your older.

ECOPURA 4-in-1 PET 0.3L-1.5L RHSG-series Hot-fill monobloc equipped with electronic filler nozzles designated for filling hot beverages such as Juice ,tea,pulp beverages or those liquid mixed particles

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

RHSG24-24-16-6 | 0.33L-1.5L

Height:150-330mm

Dia: 50-115mm | 5000-6000bph | 2.2kw | SIEMENS |

RHSG24-24-18-8 | 7000-8000bph | 2.2kw |

RHSG24-24-24-8 | 10000-12000bph | 2.0kw |

RHSG32-32-32-12 | 15000-18000bph | 5.5kw |

RHSG38-38-38-14 | 18000-20000bph | 7.5kw |

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. |

Why 4-in-1 ?

Twin bottle rinsing station include chemical water rinsing and Ozonated water rinsing ensuring the performance with strict hygiene standard

High quality & Strict Hygiene

Production of top-quality beverages requires conditions of strict hygiene, All parts that comes into contact with the beverage are manufactured in Stainless steel 304 or 316

Contactless filling

SIEMENS PLC & Touch Screen control with Integrated and separate electro-pneumatic components

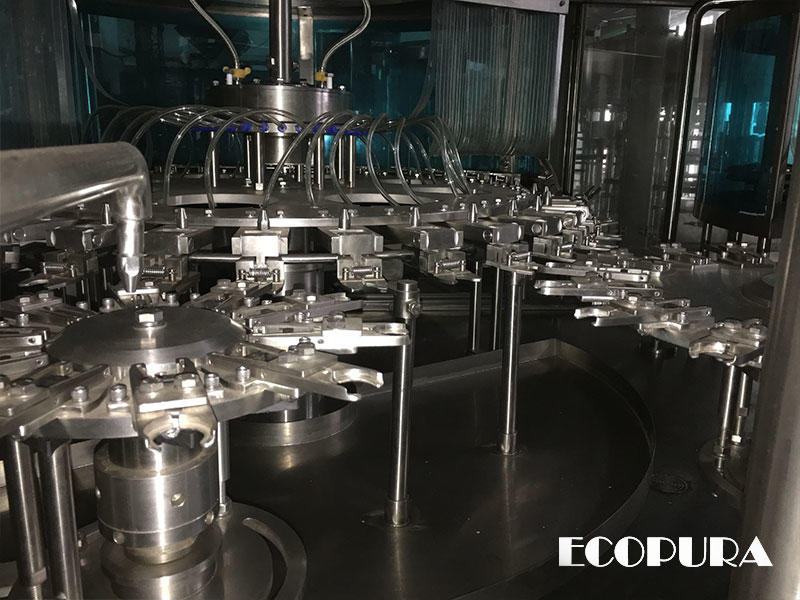

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination .The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Ozonated Water Washing Part

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination .The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

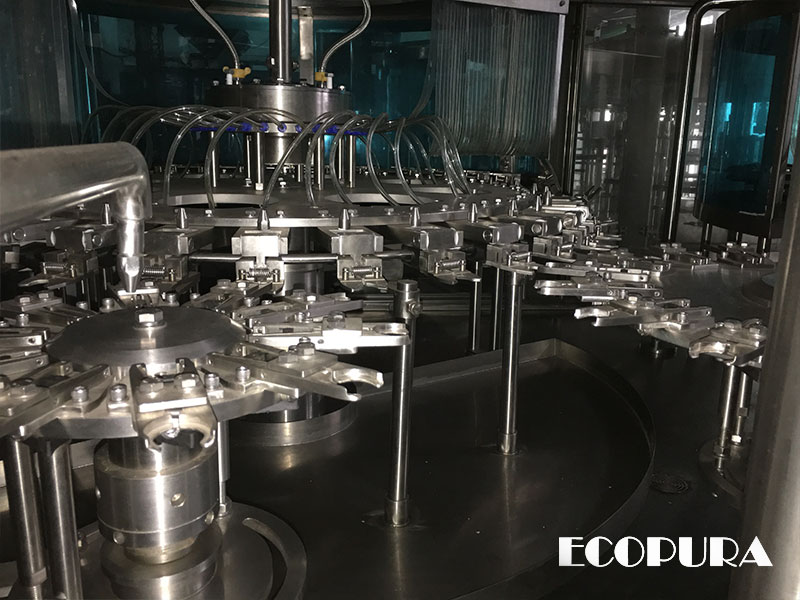

Filling Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene.

Neck-handling grippers position the PET container beneath the filling valve. Once the container has been centred, the filling process starts: Thereby, the Filling valve is opened and the product flows into the bottle with infinitely variable speed. Once the required fill volume has been reached, the flow meter provides a signal to the filling valve. The valve is now closed and the filling process completed. Dripping of the filling valve is prevented by a sieve in the product discharge. Microbiological safety by filling in a multi-chamber mode and separate return gas channel Precise determination of fill quantity via inductive flow meter Recirculation channel for heat retention of the product

Perfect flow characteristics through two filling speeds

Cleaning in a closed system using automatically positioned CIP cups

Capping Part

The capper is most precise part ensuring the machine to run credibility and product quality.The capping head applies the cap. The cap is pressed onto the bottle by means of spring pressure. At the same time it is screwed onto the thread of the bottle neck finish.As soon as the

rotation is ended and the required tightening torque is applied to the cap, a hysteresis clutch ends the capping process.

All main parts made of stainless steel AISI304 Pick station with adjustable height Torque and spring force of the capping head are adjustable Flushable cap retainer Motorised height adjustment of the capper top part with bottle selection feature

Caps online Sterilization

ECOPURA dedicated in every process details to control the hygiene such as for the caps sterilizing to ensure the maximum hygiene for your all kinds beverages. Caps online sterilizer made of stainless steel 316L with built in spraying device for high pressure Ozonated pure water sterilizing

EcoPura is recognized by numerous people at home and abroad in juice bottling machine market.

2. juice filling machine is made from the revolutionary technology.

3. We uphold our reputation for integrity in the marketplace and provide an ethical work environment for all our employees. We do the right thing each time we face a tough decision. Inquire! Currently, we are committed to getting more customers. Under this, we change the way we get along with our customers. We improve customer engagement, reassess our service solution, and developing products more targeted. In this way, we are confident to get big-name customers. We strive for sustainable growth, offering responsible products at an affordable price. Using our expertise, we support more sustainable consumption patterns by reducing the environmental impact of our products.