Company Advantages1. EcoPura juice bottle filling machine has been tested based on the following test regulations. They include energy efficiency, energy consumption, working temperature, startup time, etc.

2. The defective product will not be sent to customers thanks to the strict quality control.

3. This product is provided together with several customized options as per the demands of the clients.

4. The product is highly demanded all across the globe with vast economic effectiveness.

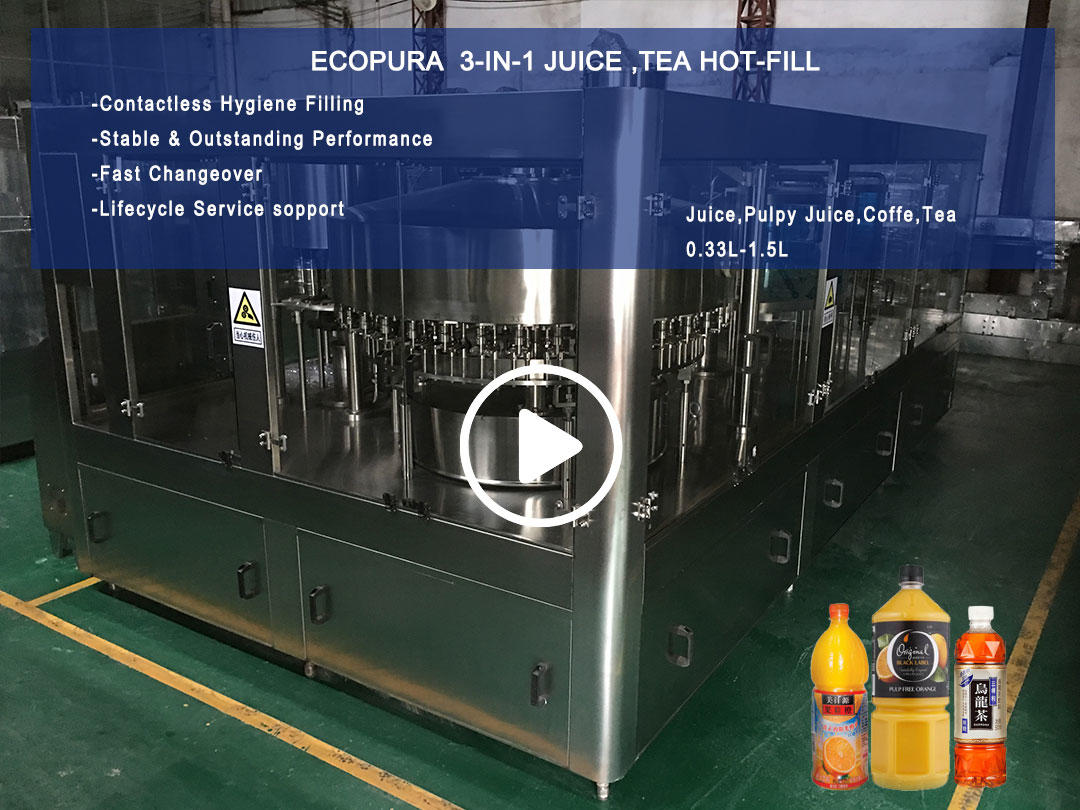

ECOPURA 3-in-1 PET 0.3L-1.5L RHSG-series Hot-fill monobloc equipped with electronic filler nozzles designated for filling hot beverages such as Juice ,tea,pulp beverages or those liquid mixed particles

Model |

Bottle Spec |

Capacity Cal@500ML | Power | PLC & HMI |

DHSG16-16-12-6 | 0.33L-1.5L

Height:150-330mm

Dia: 50-115mm |

3000-3500bph |

1.8kw | SIEMENS |

DHSG24-24-16-6 | 4000-5000bph | 2.2kw |

DHSG24-24-18-8 | 5000-6000bph | 2.2kw |

DHSG24-24-8 | 8000-9000bph | 3.0kw |

DHSG32-32-32-12 | 10000-12000bph | 5.5kw |

DHSG38-38-38-14 | 12000-15000bph | 7.5kw |

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. |

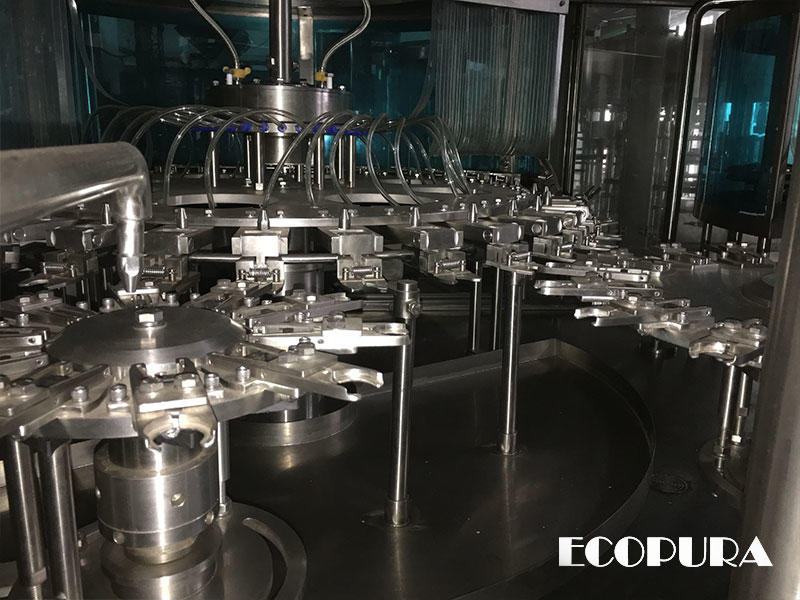

High quality & Strict Hygiene

Production of top-quality beverages requires conditions of strict hygiene, All parts that comes into contact with the beverage are manufactured in Stainless steel 304 or 316

Contactless filling

SIEMENS PLC & Touch Screen control with Integrated and separate electro-pneumatic components

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination. The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Filling Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene.Neck-handling grippers position the PET container beneath the filling valve. Once the container has been centred, the filling process starts: Thereby, the Filling valve is opened and the product flows into the bottle with infinitely variable speed. Once the required fill volume has been reached, the flow meter provides a signal to the filling valve. The valve is now closed and the filling process completed. Dripping of the filling valve is prevented by a sieve in the product discharge. Microbiological safety by filling in a multi-chamber mode and separate return gas channel Precise determination of fill quantity via inductive flow meter Recirculation channel for heat retention of the product Perfect flow characteristics through two filling speeds Cleaning in a closed system using automatically positioned CIP cups

Capping Part

The capper is most precise part ensuring the machine to run credibility and product quality.The capping head applies the cap. The cap is pressed onto the bottle by means of spring pressure. At the same time it is screwed onto the thread of the bottle neck finish. As soon as the rotation is ended and the required tightening torque is applied to the cap, a hysteresis clutch ends the capping process. All main parts made of stainless steel AISI304 Pick station with adjustable height Torque and spring force of the capping head are adjustable Flushable cap retainer Motorised height adjustment of the capper top part with bottle selection feature

Caps online Sterilization

ECOPURA dedicated in every process details to control the hygiene such as for the caps sterilizing to ensure the maximum hygiene for your all kinds beverages. Caps online sterilizer made of stainless steel 316L with built in spraying device for high pressure Ozonated pure water sterilizing

EcoPura is one of the leading supplier within the juice filling equipment industry.

2. Fully implementing technical research helps EcoPura become a leading juice filling machine supplier.

3. We attach great importance to environmental protection. We have strengthened production control and made more efficient use of materials, hoping to result in less scrap. Sustainability is what we strive for our long-term success. We are exploring new ways to increase energy efficiency and reduce waste in our daily production processes. We establish an effective and efficient control system for waste and resources, with the aim of safeguarding the health and welfare of the community from any adverse environmental issues. All of the wastes will be treated by specific waste management facilities before discharge. We take steps to formalize our environmental practices through the development of environmental policy. This will involve understanding and recording key environmental impacts, investigating opportunities for reducing these impacts.