ECOPUR manufactures a full line of sea water desalination systems designed for heavy-duty or continuous service in marine applications on and off shore.

Commercial SWRO Series Capacity

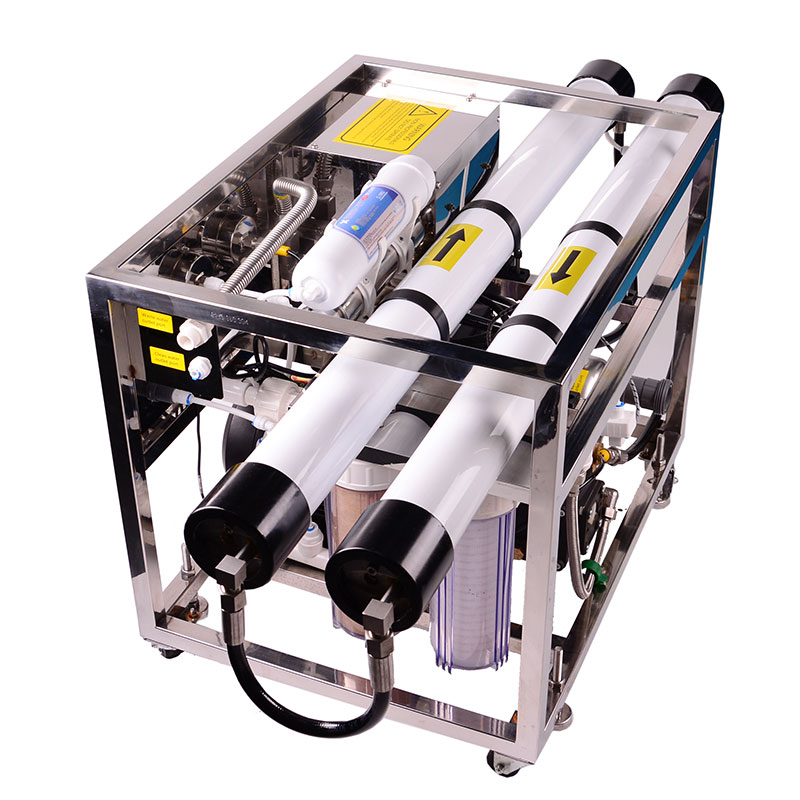

When your needs demand continuous-duty, commercial-grade water making, the solution is very clear. The EcoPura SWRO Series is efficient and extremely reliable. These water makers systems deliver great volumes of potable fresh water with capacities ranging between 380 to 10,000 GPD. Ideal for commercial vessels, island homes, oil platforms, hotels, or large yachts. SWC commercial water makers will provide wherever clean, pure, fresh water is needed. Employing our advanced microprocessor control panel, SWC commercial reverse osmosis unit enables advanced, total control and user-friendly system customization.

Operation Specifications | ||

Max. feed water temperature: 42°C Equipment upgrade for TDS up to 50,000 ppm H2S, turbidity and organics must be removed | Feed water TDS: 10,000-42,000 ppm Operating pressure: 700 to 1,000 ps pH tolerance range: 3-11 | Feed water pressure: 40 to 80 psi Antiscalant dosing is required Max. Iron content: 0.05 ppm |

Model | Capacity | Membranes | ||

GPD | M3/D | Size | Qty | |

SWRO380 | 380 | 1.4 | 2.5" x 40" | 1 |

SWRO700 | 700 | 2.7 | 2.5" x 40" | 2 |

SWRO1000 | 1000 | 3.8 | 2.5" x 40" | 3 |

SWRO2000 | 2000 | 8 | 4" x 40" | 2 |

SWRO3000 | 3000 | 11 | 4" x 40" | 3 |

SWRO3800 | 3800 | 14 | 4" x 40" | 4 |

SWRO4700 | 4700 | 18 | 4" x 40" | 5 |

SWRO5600 | 5600 | 21 | 4" x 40" | 6 |

SWRO6000 | 6000 | 23 | 4" x 40" | 7 |

SWRO7600 | 7600 | 29 | 4" x 40" | 8 |

SWRO10000 | 10000 | 38 | 4" x 40" | 10 |

Operation Specifications | Available Options | |

Powder coated steel frame Heavy duty 5 micron cartridge prefilter Sea water resistant SS pump Microprocessor/PLC based control panel & VFD Glycerin-filled 316 SS prefilter pressure gauges Product & reject flow meters TFC spiral wound membranes FRP membrane housings 380V/3Ph/50Hz power supply Low & high pressure switches Permeate TDS monitor Stainless steel high pressure piping Stainless steel throttling valve for reject stream Automatic feed shut off valve Energy recovery on 64K GPD and larger | Booster pump 380-415V/3Ph/50Hz power supply Product tank level switch pH controller with sensor ORP controller with sensor Hour meter Cleaning skid 50 micron bag filter for open intake Carbon prefilter Multimedia prefilter UV sterilizer Custom designed units Export crating Chemical dosing units | |

The ideal applications for an Industrial Sea Water RO system include | ||

Oil Tankers Island-Based Businesses Villages & Cities Cargo Ships | Coastal Developments Hotels & Resorts Seaside Work Sites | Work Boats Fish Processing Plants Seaside Villas |

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.