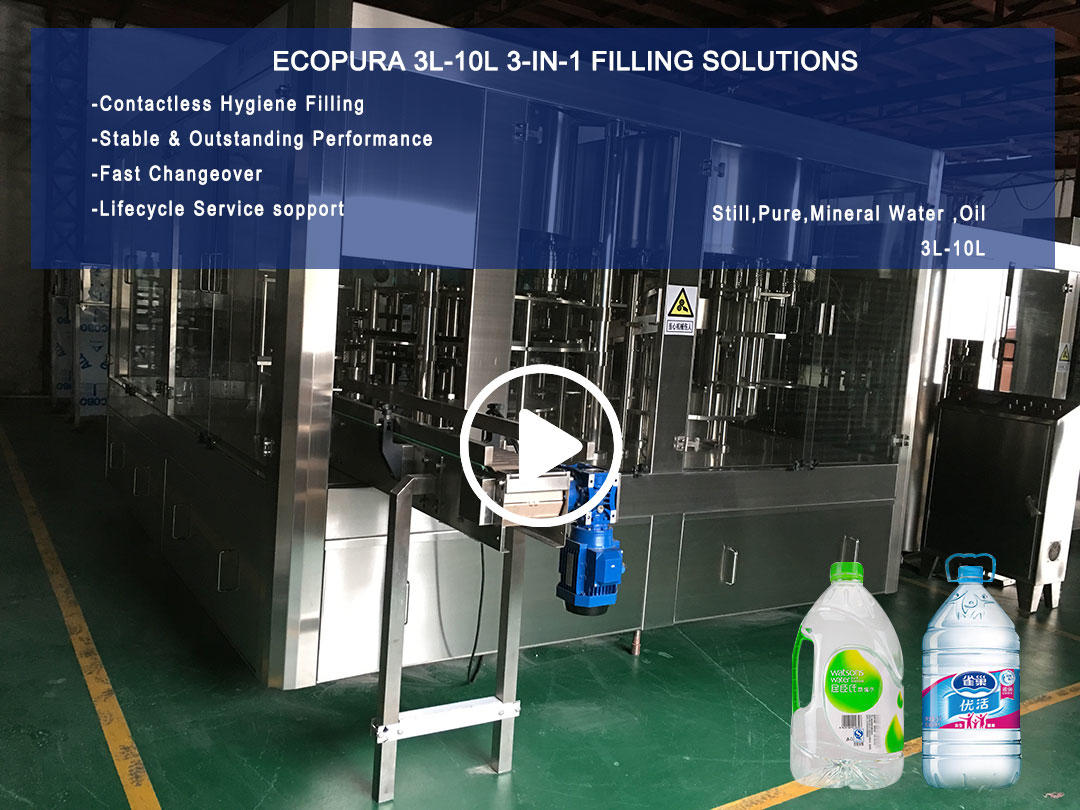

ECOPURA 3-in-1 PET 3L-10L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral, still water and other liquids etc

Model | Bottle Spec | Capacity Cal@5L | Power | PLC & HMI |

HSG10-10-5 | 3L-10L | 1200-1500bph | 2.2kw | SIEMENS |

HSG12-12-5 | 1500-2000bph | 3.0kw | ||

HSG14-14-5 | 2000-2500bph | 4.0kw | ||

HSG16-16-5 | 2500-3000bph | 5.5kw | ||

| EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

shanghai machinery CE quality electric liquid/e-liquid/e-juice filling machine manufacturer in guangzhou0086-18516347828

The electric liquid/e-liquid/e-juice filling machine manufacturer in guangzhou has progressed to the third generation, since PERWIN Packing Machinery Co., Ltd. developed the first generation of such production line in 2009. With the expansion of requirements and technology upgrading of the GMP, the mechanical and electrical design of our production line, function standardization and other aspects have been greatly improving.

The production line is suitable for a variety of doses of plastic round bottles and flat bottles.

electric liquid/e-liquid/e-juice filling machine manufacturer in guangzhou composition:

Technical Features of electric liquid/e-liquid/e-juice filling machine manufacturer in guangzhou:

1. According to user’s requirements and the bottle features, the bottle feeding at the front end of the equipment can adopt different scheme.

2. Adopting ceramic piston pump or designated by customer for precision filling metrology, the material of 316L stainless steel is used for the filling needle.

3. The specially designed inlet and outlet check valve and the precision machining to ensure not dropping when filling.

4. The manipulator driven by the precision cam can precisely crab the inner cork and tamponade stably and reliably without mistake.

5. The specially designed torque limiter, flexible connection pressure rotary buffer mechanism and individualized screw capping scheme to keep the capping torsion stable not to damage the lid and the Stability and reliability for the capping quality.

6. Having the function of not crabbing and capping without bottle, the alarm and stop running function without lid.

7. Having the automatic on-line removing function, when no lid and deflection of lid. (Optional)

8. The whole production line of intelligent control has the function of chain control for upstream and downstream working equipment.

9. The optional hundred grade laminar flow air filtration system can be optionally configured.

10. The surface of main parts of the whole production line is made of SUS 304 stainless steel, hardness of anodized aluminum alloy, non-toxic polymeric materials, etc. which comply with GMP rules.

Production capacity:

40~50 bottles/Min 80~120 bottles/Min.

Exhibition News in 2016:

Welcome to visit us!!!

See more products(click in)

FEATURES

l Economic online liquid filling machine is composed of gear pump liquid filler and conveyor.

l 7" Color LCD touch screen display and easy to preset parameters

l Electric control to finish automatic supply bottles and automatic filling liquid, if bottle not coming, it won’t fill liquid.

l Use Gear pump, Peristaltic Pump, Piston Pump or Diaphragm Pump based on customer’s requirement to measure volume of liquid and filling volume is adjustable

l The structure of machine is stainless steel 304 meeting with GMP requirement

l Speed is adjustable by electron speed regulator and easy to change the production speed.

APPLICATION

l Widely used for automatic liquid filling to bottles or container

l Based on different liquid status and using different pump

SPECIFICATION

l Model No.: ELF-1001

l Pump Type: Magnetic Gear Pump (For easy flow liquid without granules)

l Pump Material: Gear is peek with stainless steel cover

l Filling Volume: 10-3000ml

l Nozzle Quantity: 1-2pcs

l Production Capacity: 10-20bottles/min. (According to user’s requirement to design machine)

l Filling Accuracy: ±1-2% (Depends on filling volume, pumps type etc.)

l Belt width: 80mm (Others belt size can be custom made)

l Power Source: AC220V; 50HZ;1P

l Dimension: 2000x600x1400mm

l HIM: Simens Touch Screen

For real shipment freight, please consult with us

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.