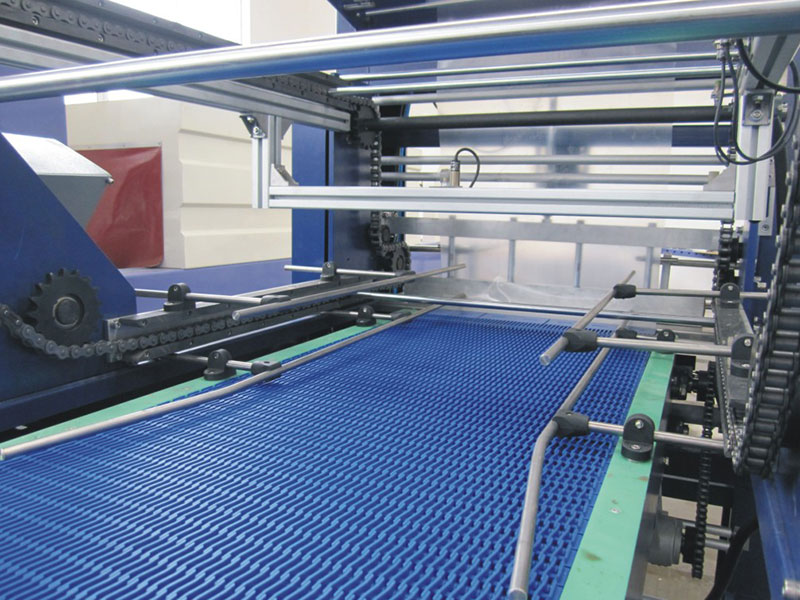

The system is equipped frequency-controlled speed conveyor with bottle sorting lane, film guiding system, wrapping, shrinking tunnel, Operability thanks to a user friendly human machine interface (HMI) , 100% automated from product infeed all the way down to the tunnel outfeed is synchronized with the PLC control system.Used for Water,Juice,tea,wine, beer etc other containers post packaging.

Model | SWP45 |

Packing Speed | 40-45Pack/min |

Packing Standard | 2*3,3*3,3*4,4*4,4*5,4*6bottles/pack |

PLC & Touch Screen | Siemens |

Air Cylinder | Airtac |

Sensor and relay | Omron, SMC |

Assembled Size | 12000*1560*2600mm |

Wrapper Part Size | 3200*1560*2600mm |

Shrink Tunnel Size | 4000*1300*1840mm |

Conveyor | 4800*1080*920mm (height adjustable) |

Sealing & Cutting time | 0.5-1s |

Working Air pressure | 0.6-0.8Mpa |

Weight | 5500kgs |

Total Power | 60kw |

♦ 1. Touch screen with friendly interface convenient for man-machine communication and operation

♦ 2. With automatic functions of bottles feeding and sorting, wrapping, sealing shrinking, cooling and shaping. can handle different packing combination

♦ 3. The quick seal cooling function ensure the package with a higher strength even in high speed production condition.

♦ 4. The inductive switch controls the film feeding system to reliably adjust and control film feeding length with less loss

♦ 5. Unique centrifugal thermal air circulation system that has an equal heat distribution ensuring outstanding and durable shrinkage shape.

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.