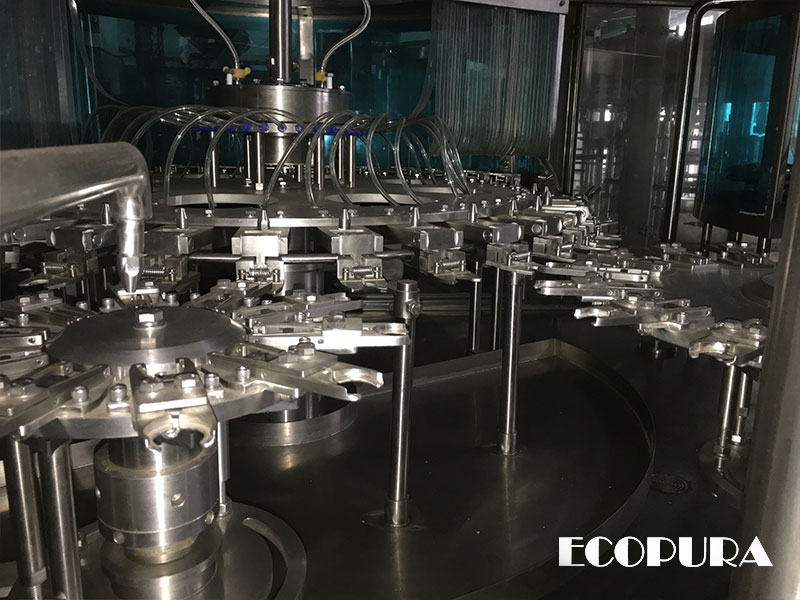

ECOPURA 3-in-1 PET 0.3L-1.5L DHSG-series monobloc equipped with isobaric filler nozzles designated for filling carbonated beverages such as Cola, beer, carbonated water and other liquids etc

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

DHSG16-12-6 | 0.33L-1.5L | 3000-3500bph | 1.8kw | SIEMENS |

DHSG24-16-6 | 4000-5000bph | 2.2kw | ||

DHSG24-18-8 | 5000-6000bph | 2.2kw | ||

DHSG24-24-8 | 8000-9000bph | 3.0kw | ||

DHSG32-32-12 | 10000-12000bph | 5.5kw | ||

DHSG38-38-14 | 12000-15000bph | 7.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Washing Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene.The PET container is first pressed on by the PET lifting unit and pressurised afterwards. Once the same pressure is in the ring bowl and the PET container, the filling valve will be opened and the filling process starts. The liquid is gently fed via a swirl insert into the bottle. Two different filling speeds guarantee optimum flow behaviour. A flow meter monitors the fed liquid quantity. Once the exact filling volume has been reached, the flow meter provides a signal and the valve closes electro pneumatically Maximum flexibility − Filling of non-carbonated and carbonated products on one system Maximum filling accuracy − Precise determination of fill quantity via inductive flow meter Gentle product treatment during filling − Low-foam and low-turbulence filling vias wirl insert in the valve Hygiene and stable filling processes − Separate gas channels for pressurization and snifting ECOPURA filling machines in their standard version are suitable for CIP and beverage mixer

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.