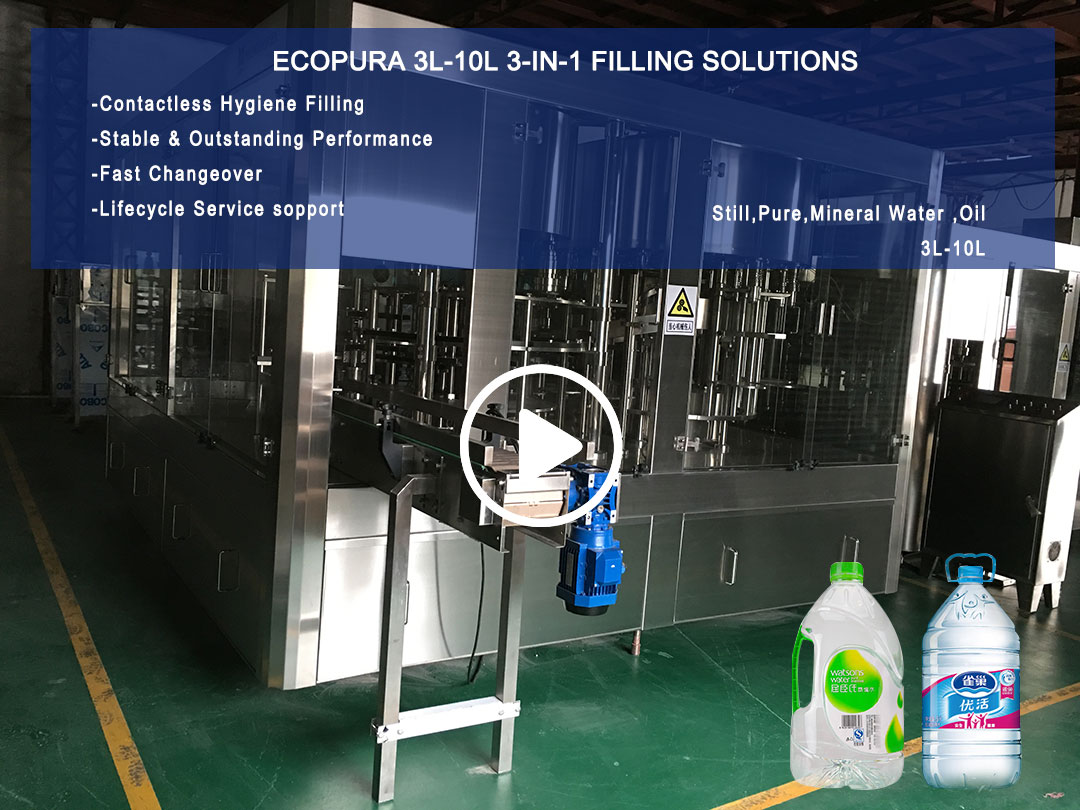

ECOPURA 3-in-1 PET 3L-10L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral, still water and other liquids etc

Model | Bottle Spec | Capacity Cal@5L | Power | PLC & HMI |

HSG10-10-5 | 3L-10L | 1200-1500bph | 2.2kw | SIEMENS |

HSG12-12-5 | 1500-2000bph | 3.0kw | ||

HSG14-14-5 | 2000-2500bph | 4.0kw | ||

HSG16-16-5 | 2500-3000bph | 5.5kw | ||

| EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.