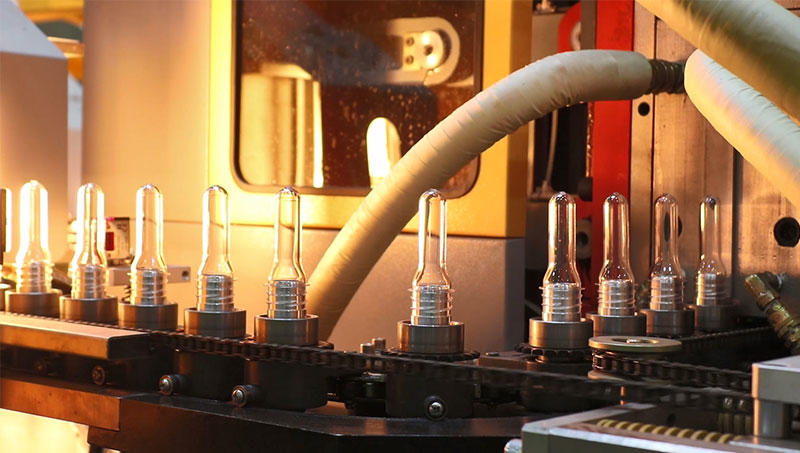

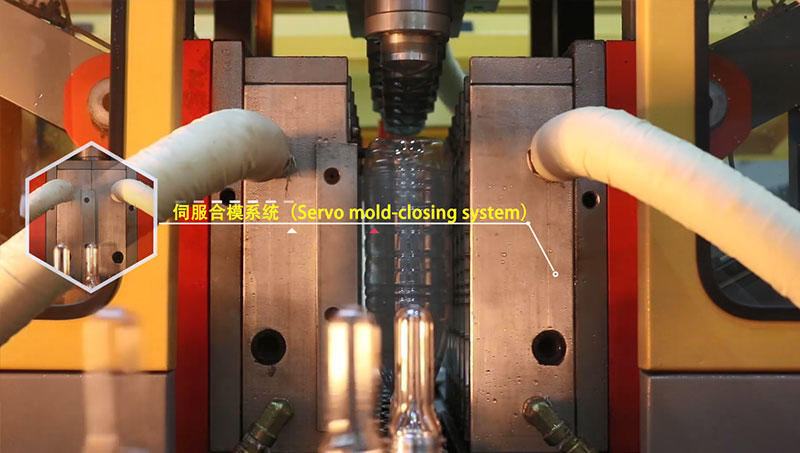

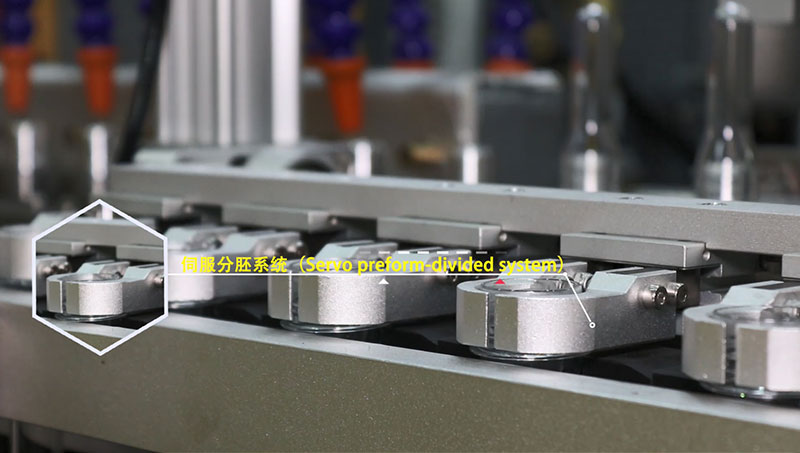

Over the years, EcoPura continuously optimized our design and technology innovation, we launched our latest blower EPC-6E ,9E, high speed blow molding machine with fully servo motor drive, can reach stable capacity of 9600bph-12000bph with highly intelligent, simply operate, energy saving, fast changeovers and outstanding performance. Adopts Siemens PLC & Touch screen which has perfect monitoring settings, fault display, automatic calculation report, memory storage functions etc to ensure the blower production situation under control at all times. All Servo control main drive, preforms division, mould clamping and stretching;all parameters can be settled on the PLC. The complex process is completed by digitalization which is safer, faster and more accurate with high flexibility.In addition, EPC-6E Blower has a patent design for cooling device which ensures the preforms heating head temperature cooling down after bottles coming out. There is a cooling water channel under the heating unit. When preforms are heating, the cooling water channel is used to block the heat of the lamp tube. Also there is a cooling air system under the cooling water channel to cool the bottle mouth and protect the tooth mouth from distortion. EcoPura unique innovative linear design structure with high blowing speed, sustainable 24-hour production, independent blowing valve group reduce production energy consumption!EPC-6E,9E Blower mainly used for blowing Water/CSD/Juice beverage bottle, Oil bottle ,condiment bottle ,cosmetic bottle and other packaging containers

Model | EPC-6EL | EPC-9EL |

Mold Cavities | 6 | 9 |

Speed | 9600bph | 12000bph |

Bottle Size | Up to 0.75L | Up to 0.75L |

Bottle Height | <245 mm | <245 mm |

Bottle Neck | Φ18-Φ38 mm | Φ18-Φ38 mm |

Bottle Body Diameter | Φ68 mm | Φ68mm |

Working Pressure | 7-9kg/cm2 | 7-9kg/cm2 |

Low Pressure Air Consumption | 2000L/min | 2000L/min |

Blowing Air Pressure | 25-35kg/cm2 | 25-35kg/cm2 |

High Pressure Air Consumption | 6000L/min | 8000L/min |

Heating lamp | 48pcs | 72pcs |

Installation Power | 96kw | 110kw |

Practical Power | 30-50kw | 40-60kw |

Machine Size | L4.5m*W2.2m*H2.3m | L5.8m*W2.2m*H2.4m |

Weight | 7500kgs | 9500kgs |

♦ Servo Control all process

♦ Electrical components are World famous brand: FESTO, Schneider, Omron etc

♦ Visibility, maintainability, standardized components, Safety

♦ A Scrap rate of under 0.1%

♦ Up to 99% production efficiency

♦ Changeovers in less than 30mins

♦ Oven electrical consumption cut by up to 25%-30%

♦ Compressed air saving up to 20%-25%

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.