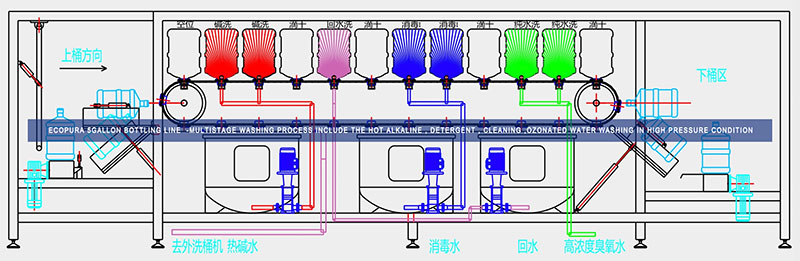

ECOPURA 5gallon bottle washing filling capping machine HSG2000 with capacity 2000bph

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Customize Guide

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

- Propose before buying the sauce paste and honey packing machine:

1) What’s packaging material?

(In order to select the appropriate metering device)

2) What’s the per bag packaging capacity?

(In order to select the appropriate metering device)

3) What’s the capacity for the machine (per minute)?

(In order to select the appropriate transmission device)

4) Packaging film width or packing bag size?

(In order to select the appropriate former)

5) Sealing form?

(In order to choose the suitable sealing device)

6) Whether you need additional device or if there are special requirements?

(In order to calculate the right price)

7) If there are special requirements for the power?

(The default configuration: 200V 50Hz / 380V 50Hz)

1.Customized service can be provided to your automatic honey packing machine .

2.Periodically call visit,to make sure there is no problem of your automatic honey packing machine .

3.one year warranty for automatic honey packing machine,technician available to service at any time.

4.ensure high quality . 80% of the main parts of our products are provided by world's famous suppliers.

Basic Introduction

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

- Functions

• The automatic sauce paste and honey packing machine has bag making, measuring, filling, sealing, cutting in

one of the function, auto-complete all the packaging process, without artificial, saving labor costs.

- Overview

• The machine is compact structure, small footprint, packaging speed, high yield, especially suitable for mass

production of sauce paste packaging use.

• The machine is equipped with an adjustable metering pumps, please select the appropriate metering pump

according to package volume. Bags depends on the former, one can only do a molding specifications can be

customized according to customer requirements.

• The control system consists of PLC, frequency converter and other components, high integration, control abilit

reliable operation. Touch screen digitizing operation, more reliable and convenient. Photoelectric sensors

encoders, proximity switches, are using imported components, mechanical and electrical integration of the

machine has been perfect.

- Expansion

• Expansion device: coding device, counting device, fill gas device, exhaust device, punching device, n-bag

without cutting device, gusset bag device, feeding device, Etc.

- Material

• Packaging Material: PET/PE, PET/BOPP/PE, PET/AL/PE, PAPER/PE, PA/PE, etc, can be heat sealed.

- Scope

• Automatic sauce paste and honey packing machine for honey, syrup, jam, peanut butter, sesame paste

tomato sauce, chili sauce, chili oil, caviar, shrimp paste, salad dressing, beef sauce, seasoning sauce, cream

shower gel, cosmetics, washing Jie Jing, shampoo, lubricants and other paste materials packaging.

Technical Parameters

¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯¯

Name | Automatic Paste&Liquid packing machine |

Model | KF02-PC |

Control System | PLC / MCU |

Metering Methods | Piston metering, Metering Pumps |

Packing Speed | 30-80bags/min |

Filling Range | 3-110ml (Depending on the material may be) |

Filling Accuracy | ±1% |

Bag Size | L50-300mm W30-150mm |

Sealing way | 3 side seal , 4 side seal , back seal(pillow bag) |

Power | 1.7kw 220V AC |

Dimensions | 700*770*1650mm |

Weight | 260kg |

Reliable packing machines china,packaging equipment company,pouch packing machines

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.