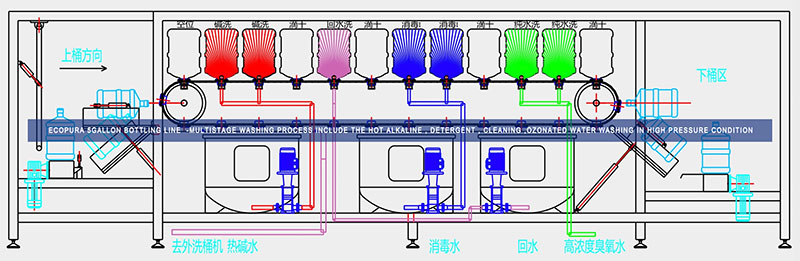

ECOPURA 5gallon bottle washing filling capping machine HSG900 with capacity 900-1000bph.

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Product Data

Three-in-one machine for PET bottle integrates the function of rinsing, filling and capping together. Based on advanced technology overseas and designed according to the filling processing demands of natural mineral water, pure water, mineralized water and etc.

Technical parameters

Model | OK-XGF14/12/4 | OK-XGF18/18/6 | OK-XGF24/24/8 | OK-XGF32/32/10 | OK-XGF40/40/12 | OK-XGF50/50/15 |

Washing heads | 14 | 18 | 24 | 32 | 40 | 50 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 |

Capping heads | 4 | 6 | 8 | 10 | 12 | 15 |

Capacity | 3000 | 6000 | 8000 | 12000 | 20000 | 25000 |

Motor power | 2.2KW | 3.7KW | 5.5KW | 7.5KW | 11KW | 15KW |

Product Details

1,The air conveyor is directly connected with bottle-in star wheel. The bottle is transferred by neck holding.

2,High speed filling line is of clamp transferring technology. Bottle shapes are more varied, and the working table inside the machine is more laconic.

3,By 3-in-1 monoblock, the bottle goes through rinsing, filling and capping with little abrasion, and the transferring is stable, bottle changing is easier.

4,Specially designed stainless steel bottle clamp dose not contact the thread parts of the bottle neck, avoiding the second contamination.

5,The high speed line is of ring type pressure bearing hydraulic cylinder.

6,High speed and large flow filling valve assures the high filling speed and exact fluid level.

7,Spares contact with the liquid are all of excellent stainless steel or food level plastic. The electric system is of international brand and achieves the national food sanitary standard.

8,The bottle-out star wheel is of screw down shape. When bottle size is changed, there is no need to adjust the transferring chain's height.

Product Picture

Our factory instruction:

1. Summarization:

We're the professional manufacture for various kinds of beverage equipment.

As mineral water pure water filling machine

pure water filling line .juice making machine .

carbonated drink cola , glass bottle beer filler machine,

Alumium cola/beer can, and etc.

All our products with Certificate: CE approved.

2. Application field :

(1). The three functions of bottle washing, filing and capping are composed

in one body of the machine . (2). The whole process is automatic . (3). So this machine has three steps , fist is washing, second is filling,

third is sealing the bottle .

3. Features:(1) Low power consumption, better material SUS 304, SUS 316. (2) Small size,simple structure,low investment (3) Auto complete line, need less worker .

4. Project design:

We can design any project of the completer line to meet the demands of our clients, considering both factory layout and the produce line .

Shanghai OK machinery Co., Ltd. was established in 2000, It's a professional manufacturer of liquid food and beverage equipment.

We have good experience especially in filling and capping technology and they provide customized service and turnkey project.

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.