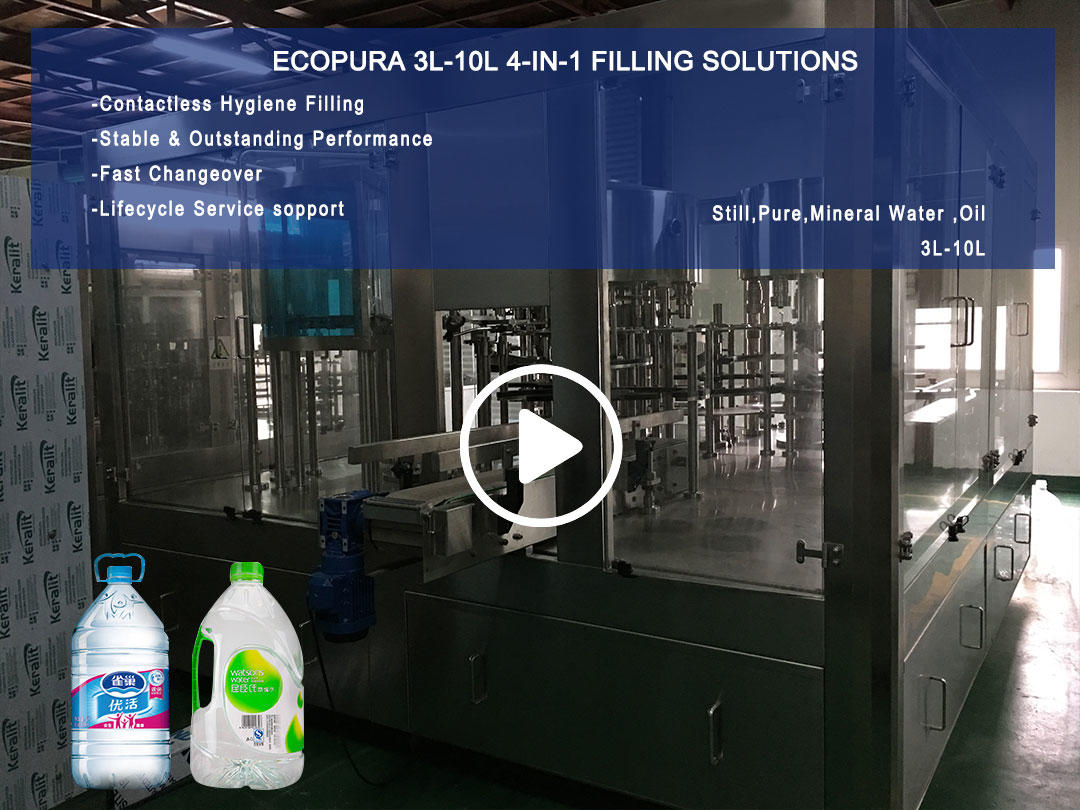

ECOPURA 4-in-1 PET 3L-10L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral, still water and other liquids etc

Model | Bottle Spec | Capacity Cal@5L | Power | PLC & HMI |

HSG10-10-5 | 3L-10L | 1200-1500bph | 2.2kw | SIEMENS |

HSG12-12-5 | 1500-2000bph | 3.0kw | ||

HSG14-14-5 | 2000-2500bph | 4.0kw | ||

HSG16-16-5 | 2500-3000bph | 5.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Why 4-in-1 ?

Twin bottle rinsing station include chemical water rinsing and Ozonated water rinsing ensuring the performance with strict hygiene standard

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us.

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination

The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Filling stoppering and capping machine suitable for eye drops and all kinds of bottle packaging,stoppering,capping three-piece this machine complete automatic liquid filling,manipulator add stoppering and cap,capping;According to customer technological reqirements configuration can add stoppering,N0 stopping no add cap;The machine stoppering and add cap structure upgrading by Shengguan company technical team,stoppering and add cap structure use manipulator,precise alignment,finished pass rate more than 99.9%.This machine performance stable.According packaging materials can be customized,Increase isolation protection system can complete aseptic produce.According to customer technological requirements configuration can satisfy different specifications and production speed.

| Applicable specification | 2-20ml |

| Production speed | Single head:40-55bottle/min Double head:60-100bottle/min |

| Filling error | ±1~2% |

| Stoppering and add cap pass rate | >99% |

| Purify compressed air pressure and air consumption | 0.3-0.5MPa,1-3m³/h |

| Power supply | 380/220v,2.5KW |

| Dimension | 4000*2000*1750mm |

| Weight | 950KG;1200KG |

FEATURES

l Economic online liquid filling machine is composed of gear pump liquid filler and conveyor.

l 7" Color LCD touch screen display and easy to preset parameters

l Electric control to finish automatic supply bottles and automatic filling liquid, if bottle not coming, it won’t fill liquid.

l Use Gear pump, Peristaltic Pump, Piston Pump or Diaphragm Pump based on customer’s requirement to measure volume of liquid and filling volume is adjustable

l The structure of machine is stainless steel 304 meeting with GMP requirement

l Speed is adjustable by electron speed regulator and easy to change the production speed.

APPLICATION

l Widely used for automatic liquid filling to bottles or container

l Based on different liquid status and using different pump

SPECIFICATION

l Model No.: ELF-1001

l Pump Type: Magnetic Gear Pump (For easy flow liquid without granules)

l Pump Material: Gear is peek with stainless steel cover

l Filling Volume: 10-3000ml

l Nozzle Quantity: 1-2pcs

l Production Capacity: 10-20bottles/min. (According to user’s requirement to design machine)

l Filling Accuracy: ±1-2% (Depends on filling volume, pumps type etc.)

l Belt width: 80mm (Others belt size can be custom made)

l Power Source: AC220V; 50HZ;1P

l Dimension: 2000x600x1400mm

l HIM: Simens Touch Screen

For real shipment freight, please consult with us

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.