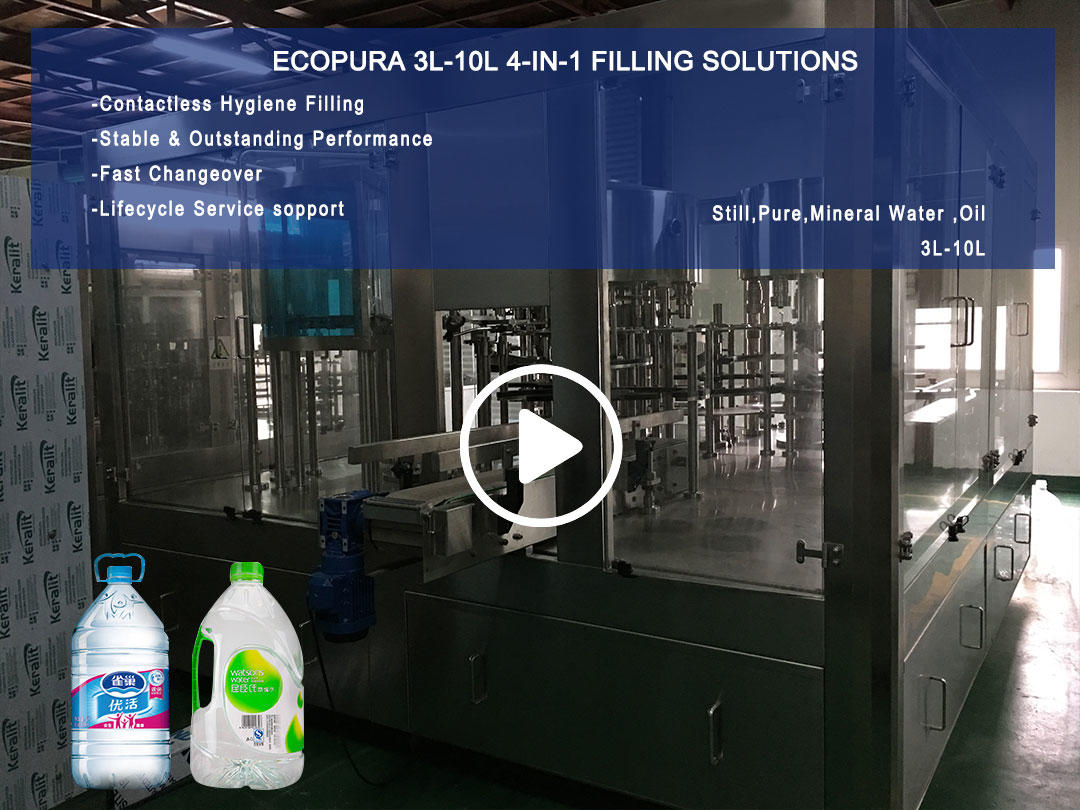

ECOPURA 4-in-1 PET 3L-10L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral, still water and other liquids etc

Model | Bottle Spec | Capacity Cal@5L | Power | PLC & HMI |

HSG10-10-5 | 3L-10L | 1200-1500bph | 2.2kw | SIEMENS |

HSG12-12-5 | 1500-2000bph | 3.0kw | ||

HSG14-14-5 | 2000-2500bph | 4.0kw | ||

HSG16-16-5 | 2500-3000bph | 5.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Why 4-in-1 ?

Twin bottle rinsing station include chemical water rinsing and Ozonated water rinsing ensuring the performance with strict hygiene standard

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us.

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination

The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

MORE INFO PLEASE CONTACT BELOW

ATTN: Michael Zhu

Email: uniweighyeah.net or uniweighgmail.com

1.continuous feeding batching filling system 2.continuous lost in weight control system 3.high precision 4.combined scales

Uniweigh automatic water liquid tank lost in weight filler/ gravimetric electronic valve filler

The combined weighing system is an world advanced complex material feeding/filling system, it's widelyused for rubber, glass, cable and various industry applications. Main function is to meet the complex prescription products which needs precise feeding requirement. It can feed or fill different materials like powder, granule and liquid precisely at the same time, and the liquid filling scale can also keep warming the liquid output through its liquid heating rubber tubes, which can meet special chemicial liquid condition requirement. and the whole system is extandable for multi scale working, which allows user to feed or fill more than 10 different materials at the same time. It's very suitable for various condition materials precise feeding.

High pressure liquid dosing pump for continous filling Built in blender for good liquid flowing optional Dynamic weighing precision 1/100 Minimium resolution 1g Standard weighing capacity: 0-10kg customerized Standard Speed: 4-20kg/h customerized Output: Spray gun for even filling

Hollow single screw output Built in blender for good granule flowing optional Dynamic weighing precision 1/100 Minimium resolution 1g Standard weighing capacity: 0-50kg customerized Standard Speed: 200-800kg/h customerized

Hollow single screw output Built in blender for good powder flowing optional Dynamic weighing precision 1/100 Minimium resolution 1g Standard weighing capacity: 0-10kg customerized Standard Speed: 0.5-5kg/h customerized

User can combine more than 3 scales to feed multi materials at the same time, like 2 granule, 2 powder, 1 liquid, which extends to 5 scales. It's also customerized.

Performance specifications

Name | Output material feeding range | Control Accuracy | Sensor range (kg) | Static accuracy |

Powder scale | 0.5~2.0 | <0.1% | 5 | 0.05% |

Liquid scale | 5~20 | <0.1% | 50 | 0.05% |

Granule scale | 300~600 | <0.1% | 100 | 0.05% |

Static measuring accuracy | 0.02% |

Dynamic Control accuracy | ±0.1% |

Output range of material | (0.5-1000)kg/h |

Output mode of material | Screw/Helex(powder) or Measurement Pump, valve pipe (liquid) |

Container mounting screw, overload protection, platform mounting board

Water proof loadcell, waterproof cable

Batching signal

MORE INFO PLEASE CONTACT BELOW

ATTN: Michael Zhu

Email: uniweighyeah.net or uniweighgmail.com

Warranty:

1 year for electronic parts.

Contact Person: Gina Zhou

-----------------------------------------------------------------------------------------------

Skype: live:zhoumllk

WeChat: z793168374

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.