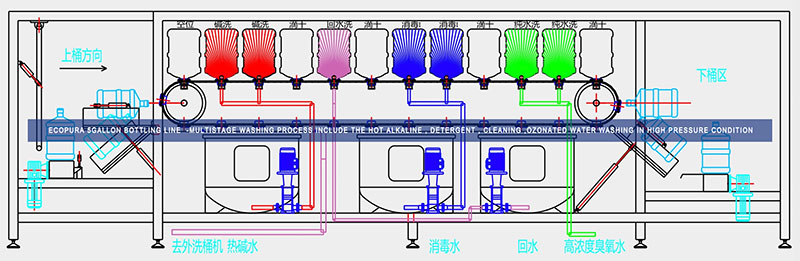

ECOPURA 5gallon bottle washing filling capping machine HSG900 with capacity 900-1000bph.

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Liquid or Soft drink Pneumatic filling machine

Application:soft drink or other liquids .

Filling Range:5-100ml,10-300ml,50-500ml,100-1000ml,500-2500ml,1000-5000ml

1.The equipment is mainly used in food, daily chemical, pesticide, medicine and special industry.

2.This machine have two filling method: foot control and semi auto filling , two filling ways can be arbitrarily switched.

3.this machine adopts rotary valve for wear resistance, acid resistance, high temperature resistant PTFE material, can not beat, collision when cleaning it.

4.Actual operation of removable barometer, easy to clean and repair the machine ,Easy for machine normal operate

5.This equipment is simple and reasonable, easy to operate and understand, high precision

2019 Hot Sell Automatic Small PET Bottle Mineral/Pure Water Bottling Filling Machine Price

1.water production line

2.Bottle washing machine

3.Bottle filling machine

4.Bottle capping machine

2000-36000BPH automatic bottled mineral water filling machine integrates washing , filling and capping into one unit, it can be used for filling production of different kinds of liquid. such as pure water ,mineral water ,soda water etc .

Model | CGF14125 | CGF16166 | CGF24246 | CGF323210 | CGF404012 |

washing, filling and capping heads | 14-12-5 | 16-16-6 | 24-24-6 | 32-32-10 | 40-40-12 |

Production capacity (b/h) | 4000-5000 | 7000-8000 | 8000-12000 | 12000-15000 | 16000-20000 |

suitable bottle specification | φ=50-110=170 330-2250ml | ||||

Washing pressure(kg/cm 2 ) | 2-3 | ||||

Motor power(kw) | 2.2kw | 3kw | 5.5kw | 7.5kw | 11kw |

Overall dimensions(mm) | 2600×1920×2550 | 3100×23002800 | 3800×2800×2900 | 4600×2800×2900 | 5450×3300×2900 |

Weight (kg) | 3000 | 4000 | 6000 | 8000 | 9500 |

2019 Hot Sell Automatic Small PET Bottle Mineral/Pure Water Bottling Filling Machine Price

Production Line

Water treatment system

2019 Hot Sell Automatic Small PET Bottle Mineral/Pure Water Bottling Filling Machine Price

3 in 1 Filling machine

Sleeve labeling machine

Shrink packing machine

NO. | ITEM | BRAND |

1 | Main electronic parts | SIEMENS |

2 | Electric protection switch | SIEMENS |

3 | Circuit breaker | SIEMENS |

4 | PLC | MITSUBISHI |

5 | Touch screen | SIEMENS |

6 | Transducer | MITSUBISHI |

7 | Photoelectricity switch | SIEMENS |

8 | Pneumatic element | FESTO |

Exhibition In Colombia

Welcome to visit U TECH MACHINE Company

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.