Model | EPC6L-2 | EPC6L-3 |

Mold Cavities | 2 | 3 |

Speed | 1400bph | 3000bph |

Bottle Size -Max | 6L | 6L |

Bottle Height | <400 mm | <400 mm |

Bottle Neck | <20 mm | <20 mm |

Bottle Body Diameter | <180 mm | <180 mm |

High Pressure Air Consumption | 3000L/min | 4000L/min |

Installation Power | 55kw | 150kw |

Practical Power | 20-30kw | 40-70kw |

Machine Size | L3.1m*W1.92m*H2.3m | L4.4m*W2.2m*H2.3m |

Weight | 4500kgs | 10000kgs |

♦ Stable performance with advanced PLC.

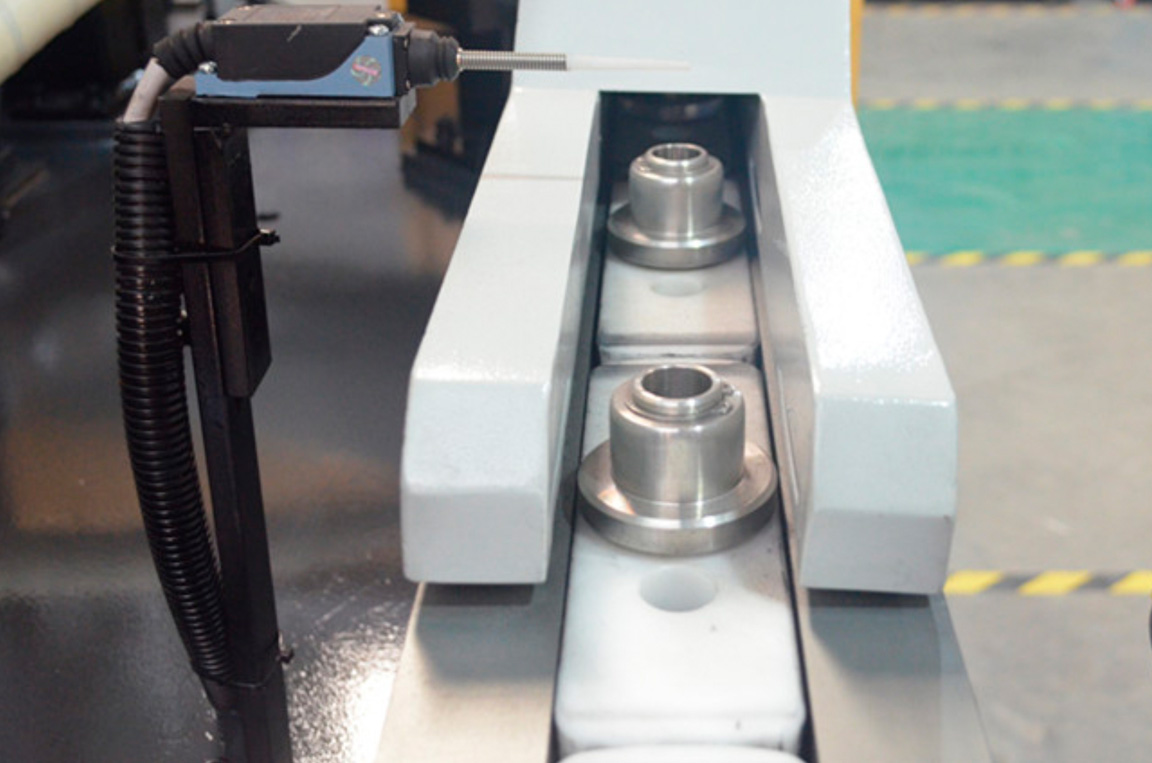

♦ Conveying preforms automatically with conveyor.

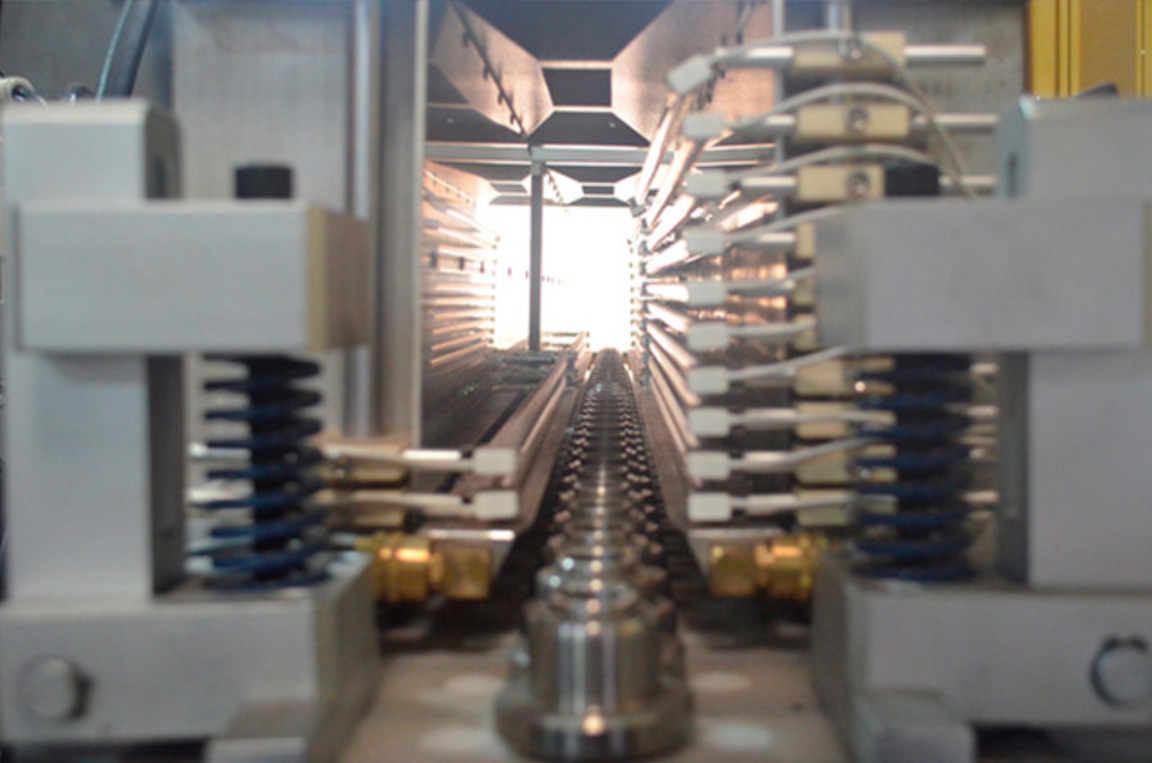

♦ Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater.

♦ High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

♦ High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

♦ No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

♦ Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

♦ Strong clamping force with high pressure and double crank links to lock the mold.

♦ Two ways of operating: Automatic and manual.

♦ Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

♦ Low cost, high efficiency, easy operation, easy maintenance, etc, with automatic technological process.

♦ Contamination is avoided for the bottle body.

♦ Ideal effect of the chilling with the chilling system.

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.