EPC-4EL,6EL Blower mainly used for blowing Water/CSD/Juice beverage bottle, Oil bottle ,condiment bottle ,cosmetic bottle and other packaging containers

Model | EPC-4EL | EPC-6EL |

Mold Cavities | 4 | 6 |

Speed | 4800-5000bph | 7200-7500bph |

Bottle Size | Up to 2L | Up to 2L |

Bottle Height | <330 mm | <330 mm |

Bottle Neck | Φ18-Φ38 mm | Φ18-Φ38 mm |

Bottle Body Diameter | Φ106 mm | Φ106 mm |

Working Pressure | 7-9kg/cm | 7-9kg/cm2 |

Low Pressure Air Consumption | 2000L/min | 2000L/min |

Blowing Air Pressure | 25-35kg/cm2 | 25-35kg/cm2 |

High Pressure Air Consumption | 6000L/min | 8000L/min |

Heating lamp | 48pcs | 72pcs |

Installation Power | 96kw | 110kw |

Practical Power | 30-50kw | 40-60kw |

Machine Size | L4.5m*W2.2m*H2.6m | L5.8m*W2.2m*H2.6m |

Weight | 6500kgs | 10000kgs |

♦ Servo Control all process

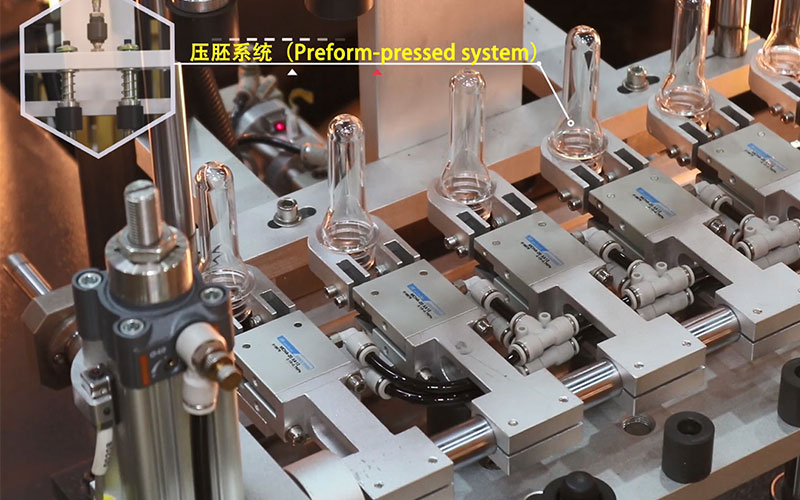

♦ Electrical components are World famous brand: FESTO, Schneider, Omron etc

♦ Visibility, maintainability, standardized components, Safety

♦ A Scrap rate of under 0.1%

♦ Up to 99% production efficiency

♦ Changeovers in less than 30mins

♦ Oven electrical consumption cut by up to 25%-30%

♦ Compressed air saving up to 20%-25%

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.