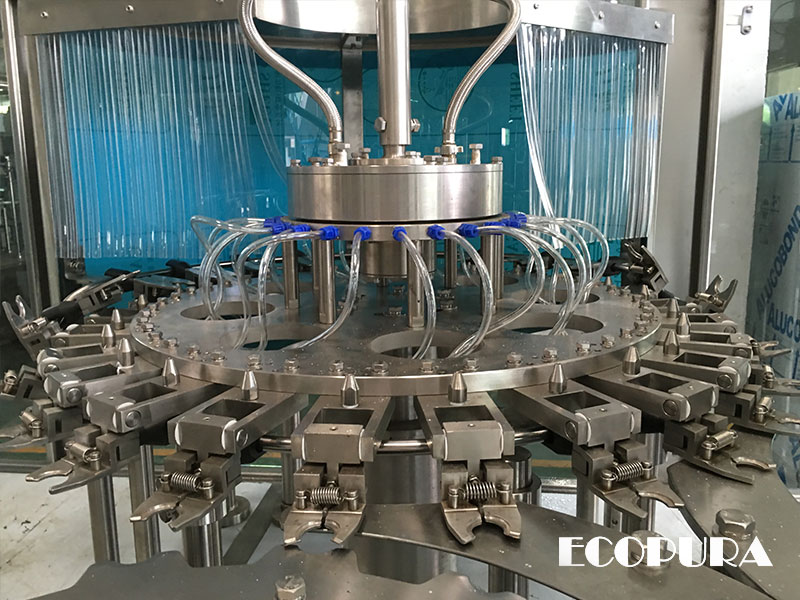

ECOPURA 3-in-1 Glass 0.3L-1.5L HSG-G series monobloc equipped with overflow filler nozzles designated for filling wine or Sparking wine

Model | Bottle Spec | Capacity Cal@500ML | Power | PLC & HMI |

HSG8-8-3G | 0.33L-1.5L | 5000-3000bph | 1.5kw | SIEMENS |

HSG16-12-6G | 3000-4500bph | 1.8kw | ||

HSG24-16-6G | 5000-6000bph | 2.2kw | ||

HSG24-18-8G | 7000-8000bph | 2.2kw | ||

HSG24-24-8G | 10000-12000bph | 3.0kw | ||

HSG32-32-12G | 15000-18000bph | 5.5kw | ||

HSG38-38-14G | 18000-20000bph | 7.5kw | ||

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

Washing Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene. The lift cylinder presses the bottle on to the filling valve where it is pre-evacuated several times. With non-carbonated beverages, the filling valve opens due to a movement of the control cylinder. With carbonated beverages, the bottle is pressurised and the valve opens as soon as the bottle and the ring bowl have the same pressure. At both of the filling processes, the liquid runs through a spreader along the bottle wall. The valve closes as soon as the bottle is entirely filled. The correction channel opens and the excessive fill quantity is displaced from the bottle to the end of the vent tube. With carbonated beverages, a snifting phase is performed in order to reduce the pressure in the bottle head space. Non- carbonated beverages can be removed from the filling valve right after filling is completed.

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.