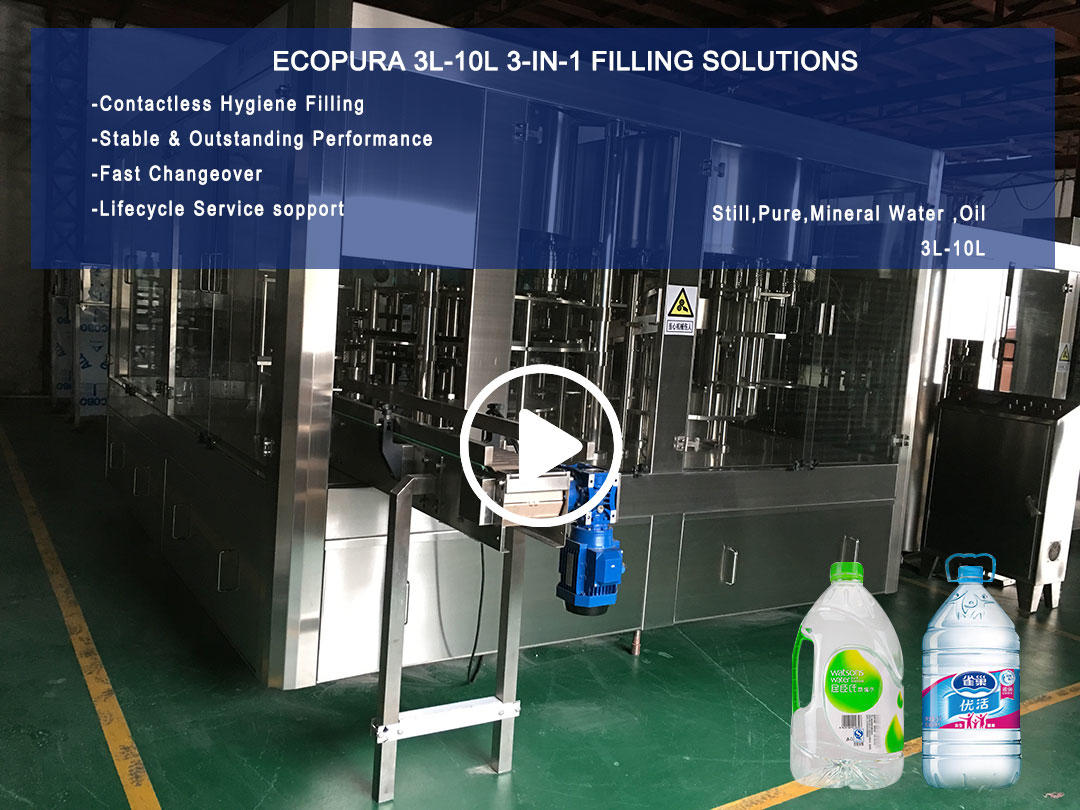

ECOPURA 3-in-1 PET 3L-10L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral, still water and other liquids etc

Model | Bottle Spec | Capacity Cal@5L | Power | PLC & HMI |

HSG10-10-5 | 3L-10L | 1200-1500bph | 2.2kw | SIEMENS |

HSG12-12-5 | 1500-2000bph | 3.0kw | ||

HSG14-14-5 | 2000-2500bph | 4.0kw | ||

HSG16-16-5 | 2500-3000bph | 5.5kw | ||

| EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. | ||||

HCGNX-I/II Type Eyedrop Filling Line

Brief Introduction:

This production line consist of Automatic Bottle Unscrambler, Bottle Washing Machine, Tunnel Type SterilizationDrier, eyedrop filling machine, Vertical Labeling machine, can complete bottle sorting, water,and gas cleaning,drying and ozone disinfection, filling, plugging, capping, labeling, mainly used in eyedrops and other small doses of solution, also can be used single independently.Meet the GMP requirement.

Characteristic:

1.It with reasonable structure, higher precision in filling, reaching the advanced level in domestic same business. Meet with requirement of GMP standard completely.

2.eyedrop filling capping machine is a third generation product, human-machine interface operation, filling by peristaltic pump

3.No bottle no filling, no plug no capping and automatically stop if cap and plug is under-supply.

Main Technical Parameters:

Filling Volume 2-30ml

Productivity 30-50bottles/min 60-80bottles/min

Water Pressure 0.3Mpa

Total Power 0.5 m3/h

Compressed Pressure 0.6-0.8Mpa

Compressed Air Wastage 300 L/min

Power Supply 380V/50Hz

Total Power 5.5 kw

Dimension 11000*1500*1900mm

1, GFK160 digital controlled liquid filling machineThe digital controlled filling machine used filling time and motor turning

2, speed to control the filling volume.

3. It's the idea filling machine widely used in food, beverages, oil, glue, cosmetics, pharmaceutical and so on low sticky and no-granule products.

4, The pump made in corrosion resisting materials,can fill oil products,heat products,acid products,alkali products and so on.

Charactors :

SUS structure,easy to clean,meet with GMP requirements.

LCD display,easy to operation

Filling nozzle used the Leak-proof designed

Automatically counting

Specification

Woking mode:electric

Max.flow:>3.2L/min

Filling range:2-3500ml

power supply:220V 30w

Filling accurate:±1%

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.