Company Advantages1. For its material, we used water bottling machine prices that was typical for liquid filler . The product can enhance the speed, accuracy, and efficiency of workers

2. With the benefit of increasing production efficiency and output, the product is widely applied in the production of many industries. Its overload protection function can effectively protect operators from harm

3. The product is characterized by its thermal resistance. The thermally conductive materials dissipate the heat through liquid cooling, natural convection, forced convection, or radiation. The product can ensure a high filtration rate

4. The product is able to negotiate the space. It has the ability to single-handedly transform a large area into multiple smaller spaces with minimal effort within a few moments. Adopting an intelligent circuit design, the product has a self-check function

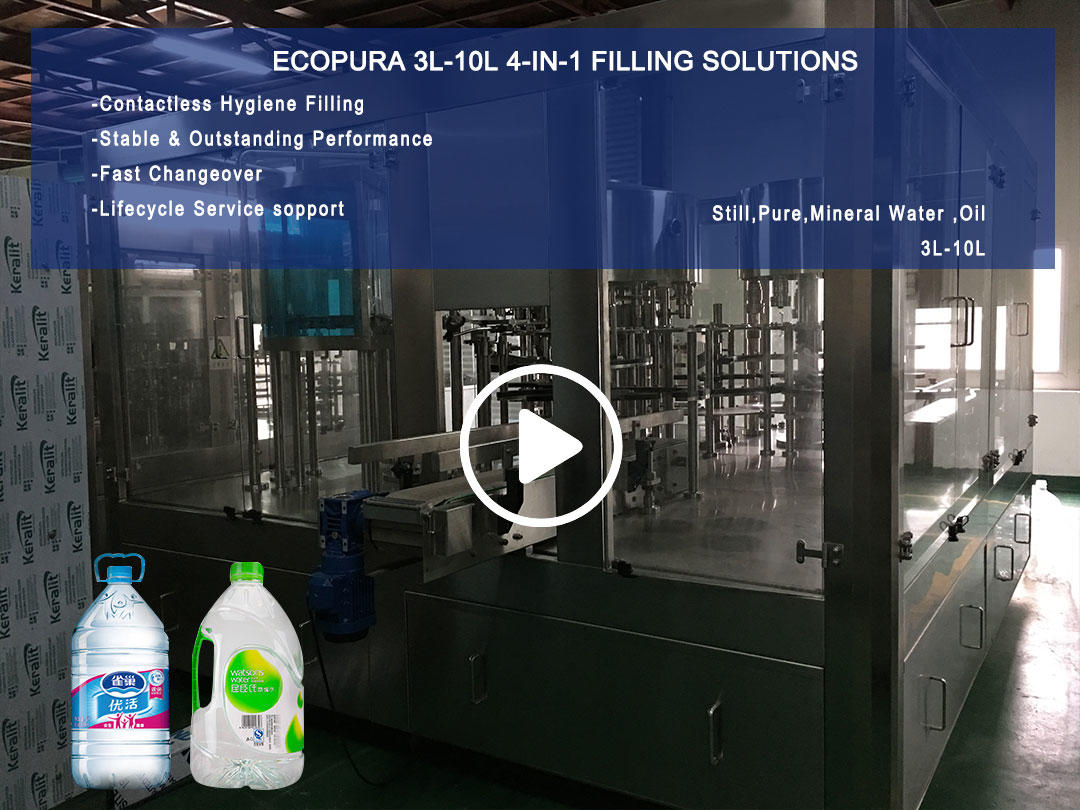

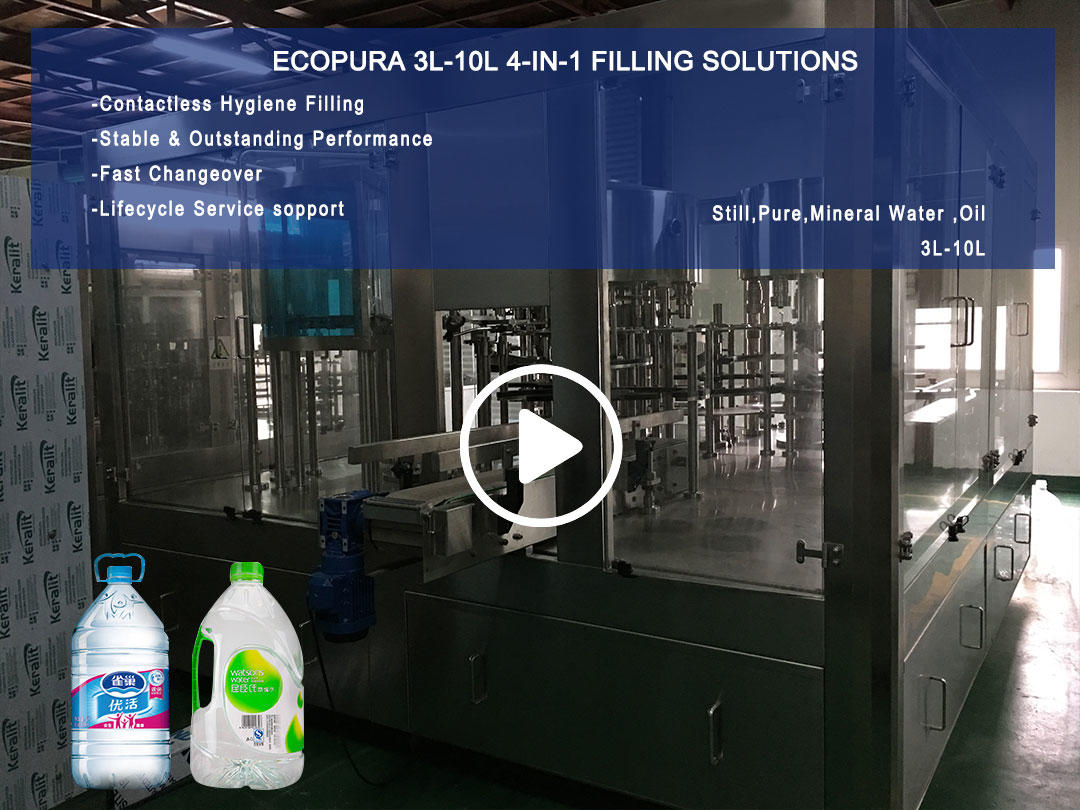

ECOPURA 4-in-1 PET 3L-10L HSG-series monobloc equipped with overflow filler nozzles designated for filling non-carbonated beverages such as pure or mineral, still water and other liquids etc

Model |

Bottle Spec |

Capacity Cal@5L | Power | PLC & HMI |

HSG10-10-5 | 3L-10L | 1200-1500bph | 2.2kw | SIEMENS |

HSG12-12-5 |

1500-2000bph | 3.0kw |

HSG14-14-5 |

2000-2500bph | 4.0kw |

HSG16-16-5 |

2500-3000bph | 5.5kw |

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us. |

Why 4-in-1 ?

Twin bottle rinsing station include chemical water rinsing and Ozonated water rinsing ensuring the performance with strict hygiene standard

EcoPura’s Filling machines are include but not-limited to above list,more info pls contact us.

High quality & Strict Hygiene

Production of top-quality beverages requires conditions of strict hygiene, All parts that comes into contact with the beverage are manufactured in Stainless steel 304 or 316

Contactless filling

SIEMENS PLC & Touch Screen control with Integrated and separate electro-pneumatic components

Chemical Washing Part

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination

The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Ozonated Water Washing Part

The machine applies unique overturning bottle clamp, Made of Stainless Steel 304 or 316 hygienic and durable. Which grips bottle at neck position, avoiding bottle mouth contamination

The high efficiency atomizing spray nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall, and saves rinsing water.

Filling Part

Stainless Steel 304 or 316 Filling valves are designed and manufactured featuring high filling accuracy and high filling speed whilst contactless filling ensures high level of hygiene.Bottom-holding position the PET container beneath the filling valve. Once the container has been centred, the filling process starts: Thereby, the Filling valve is opened and the product flows into the bottle with infinitely variable speed. Once the required fill volume has been reached, the flow meter provides a signal to the filling valve. The valve is now closed and the filling process completed. Dripping of the filling valve is prevented by a sieve in the product discharge. Microbiological safety -Contact-free filling and optimized machine design High filling accuracy -Use of flow meters and infinitely variable flow speeds High availability -Top efficiency thanks to the combination with ECOPURA cap feed systems ECOPURA standard Machines are suitable for CIP

Capping Part

The capper is most precise part ensuring the machine to run credibility and product quality.The capping head applies the cap. The cap is pressed onto the bottle by means of spring pressure. At the same time it is screwed onto the thread of the bottle neck finish. As soon as the rotation is ended and the required tightening torque is applied to the cap, a hysteresis clutch

ends the capping process. All main parts made of stainless steel AISI304 Pick station with adjustable height Torque and spring force of the capping head are adjustable Flushable cap retainer Motorised height adjustment of the capper top part with bottle selection feature

Caps online Sterilization

ECOPURA dedicated in every process details to control the hygiene such as for the caps sterilizing to ensure the maximum hygiene for your all kinds beverages. Caps online sterilizer made of stainless steel 316L with built in spraying device for high pressure Ozonated pure water sterilizing

Shenzhen EcoPura Water Equipment Co.,Ltd is important and reliable supplier of many famous companies for its liquid filler . We have dynamic professional cadres. They keep abreast of product market needs and are able to lead the trend with in-depth industry knowledge and innovative methods.

2. We have expanded our business scope covering most of North America, South America, the Middle East, Europe, Southeast Asia, and other markets based on our superb manufacturing technology.

3. The company has built up a project management team. The team has profound expertise and experience in project planning, production control, budget planning, and materials procurement. All these are quite crucial for us to provide professional service to clients. Bearing social responsibility, we are proud to be a company that focuses on the triple bottom line of profit, society, and the environment. Inquiry!