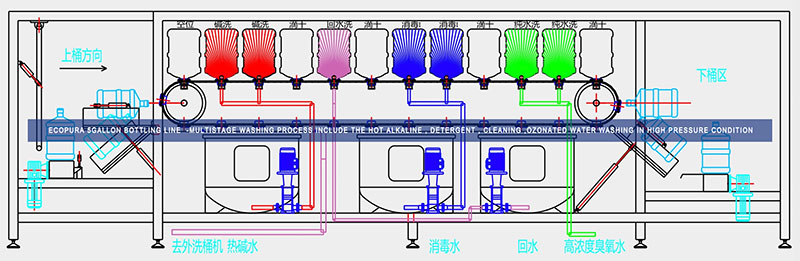

ECOPURA 5gallon bottle washing filling capping machine HSG900 with capacity 900-1000bph.

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Clean bottles are discharged out of the rinse by conveyor to feed the filler. After entering the filler, bottles are retained by bottom supporting plates, which are actuated by bottle supporting mechanism to raise them to engage with filling valves. Filling valves are opened by bottle presence signals. After finishing filling, valves are closed by valve closing mechanism to further stop venting to complete the filling process.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Best Selling Products Multi-Function Liquid Packing Companies Machine

| Product Description |

This machine is high precision packing machine and the most advanced liquid compound packing machine in china, It can automatically complete Bag-making, filling, sealing, printing, cutting and counting. Controlled by microprocessor and automatic photocell. It is widely used to pack all kinds of liquid without gas, especially soy, wine, vinegar, juice, soybean milk, peanut oil, vegetable oil, plant oil, mineral water and liquid chemical products.

Product Application: pure water, milk, soybean milk, fruit juice, beverage, soy sauce, vinegar, wine etc.

Product Function

(1) To form bag

(2)To sterilize film with violet ray

(3)To seal vertically

(4)To print date

(5)To drag bag in line

(6)To fix fill

(7)To seal horizontally

(8)To cut bag

(9)To count automatically

| TECHNICAL PARAMETERS | |||

| Production capacity | 1500-2200 Bags/H | ||

| Filling range | 300-1000ml | ||

| Film width | 320MM/380MM | ||

| Voltage | AC220V/380V (50Hz/60Hz) | ||

| Power | 1.8KW 220V/380V | ||

| Weight | 450Kgs | ||

| Size | 1100(L)×900(W)×2100(H) MM | ||

| Product Images |

| Detailed Images |

| Related Products |

| RO water treatment machine | RO water treatment machine | sachet packing machine |

| semi automatic small bottle filling machine | full automatic small bottle filling machine | 5 gallon water filling machine |

| Our Service |

| Pre-Sales Service | After-Sales Service |

|

|

| the machine. |

|

|

MOST IMPORTANT!!

WE ARE THE TRADE ASSURANCE SUPPLIERS!

| Our Company |

With years of export experience along with excellent quality, advanced services and competitive prices, Haiguang has won numerous customers' trust and support.With years of export experience along with excellent quality, advanced services and competitive prices, Haiguang has won numerous customers' trust and support.

Why Choose Us

1. Since2001,professional manufacturer of drinking water purification equipment, industrial pure water equipment, ultrapure water equipment, seawater desalting plant, brackish water equipment as well as bottled water production lines etc.

2. We have professional team, from design, manufacture, installation, which can provide the best products to you.

3. Advanced production equipment, many core machine import from Germany.

4. High quality materials, can provide customers with high-quality products.

5. As a professional team, we have full experience in this field, our products have been widely exported to different countries and regions. We have full oversea experience, not only for manufacturer, but also installation and after service.

6. Fast delivery, and good quality control team to ensure timely delivery

Electronic components imports

Certifications

| Packaging & Shipping |

1.Wooden Case ,International Standard Export Package

| |

| 2.Shipping'Delivery | Main:By Sea(Shipping): From Port Jiangmen/Shenzhen /Guangzhou |

| By Express: DHL, FedEx, UPS, TNT etc | |

| By Air: From Airport Shenzhen / Guangzhou | |

| FAQ |

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: Can you send me the video ?

A: Certainly, we have made video of every machine

Q:How to get the machine?

A:We deliver the machine to you nearest port or city and you release it.

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Pengjiang, Jiangmen City, Guangdong Province, China, about 90 minutes away from Guangzhou Baiyun Airport. All of our customers from home and abroad are welcome to visit us!

Q: How long i can get the feedback after we sent the enquiry?

A: We will reply you within 12 hours in working day.

Q: How long is the warranty of your equipment?

A: 1 year warranty after receipt check upon delivery. And we will comprehensively provide you all kinds of technical support services in after-sale !

| Contact Us Any Time: |

Company Name:Jiangmen Pengjiang Haiguang Drinking Water Equipment Co., Ltd.

Job Title : Ms.xiao yan zhu

Website: http://www.fillingmachine.cn

Website on alibaba.com: shamoquan.en.alibaba.com

Telephone: 0086-750-3230696

Fax: 86-750-3230887

Mobile Phone: 0086-13528318738

E-Mail: sale(at)fillingmachine.cn

If you want more information about our products,please contact our sales at any time!!!

1. What is your MOQ?

Answer: 1unit

2. Can your factory customize the LPG storage tank??

Answer: Yes, We can customize the LPG storage tank according to your request.

3. In what way can I contact you?

Answer: Name:Colin SUN. Email:sale06(@)equipjx.com. Tel/Whatsapp:+8618790531967.

Wechat:+8618790531967/+8618317565351

4. How long is the warranty period for the LPG storage tank?

Answer: 12 month.

5. What's the way to transport the LPG storage tank?

Answer: Use 20 feet and 40HQ container, 40FR container, Bulk carrier.

6. Do you have after-sales service in your company?

Answer: Yes. When the customer receives the LPG storage tank, we will guide the customer to install the LPG storage tank.

7. If I have my own freight forwarder in China, can you send the LPG storage tank to my agent?

Answer: OK, no problem. After you place an order, please tell us the name and telephone number of your agent. We will contact him and send the LPG storage tank to your agent's designated warehouse.

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.