Company Advantages1. The adoption of suitable equipment for EcoPura filling system manufacture increases product quality. The selection is dictated by sewing stitch type and/or seam type so as to make the manufacture successful. With a compact structure, the product can operate stably

2. mineral water bottle filling machine has passed tests of SGS, FDA, CE and etc. The product generates little noise during operation

3. It's production follows strict quality management criteria based on international standards. The product is equipped with air conveyor and frequency control

4. Strict quality control is conducted by professionals to ensure the product is always at the best quality. The product can ensure a high filtration rate

5. Our mineral water bottle filling machine can work for non-stop 24 hours. The product is energy-saving, consuming little energy

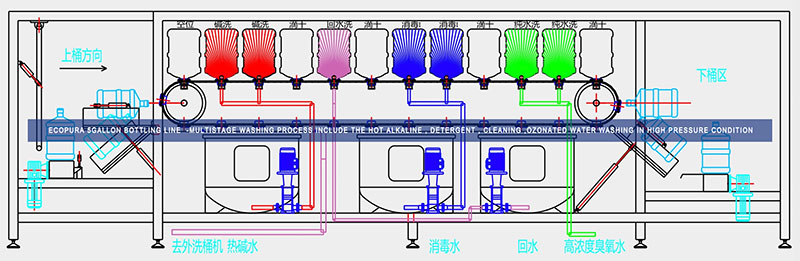

ECOPURA 5gallon bottle washing filling capping machine HSG100-HSG450 with capacity 100-450bph.

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

Bottles Sterilizing & Washing

Exclude the brusher pre-washing process for cleaning bottles inside & outside part, the pre-washed 5gallon bottles feed into the 3-in-1 washing filling capping unit which Designed Multistage high-pressure inner washing Process include Hot Alkaline washing, disinfection water washing, Dripping ,Ozonated pure water cleaning for ensuring the recycled bottles 100% clean & health, the washing system is controlled by pumping though cleaning tank and the ejecting nozzles on the bottle carrier to spraying the inner wall of the bottles by high pressure water, after finishing the washing process, the bottles will discharge though reverse turn-over mechanize and transported to the filling Part for full filling as designated volume and finally capping, discharge out the 3-in-1 by conveyor to next step

Caps Loading & washing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Quantitively Filling & Capping

Clean bottles are discharged out of washing part to filler. After entering the filler, bottles are filled contactless with qualitatively control.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

Shenzhen EcoPura Water Equipment Co.,Ltd is a pioneer among Chinese mineral water bottle filling machine manufacturers. We have grown steadily in size and profit in the overseas markets, and often win the endorsements of many well-known brands at home and abroad. We will continue to expand the overseas markets.

2. Our company has brought together the right people (highly skilled assemblers and technicians, production engineers, quality engineers, purchasing staff and more). With these people's industry know-how, we are able to create benefits for our customers.

3. We have a team of staff that are qualified and well-trained. Their keen sense of responsibility, ability to act flexibly, technical expertise, vigorous involvement, and capability to adapt themselves to different situations all directly make a contribution to the business growth. EcoPura has made determined effort to achieve the goal of being a international bottled water machine supplier. Get info!