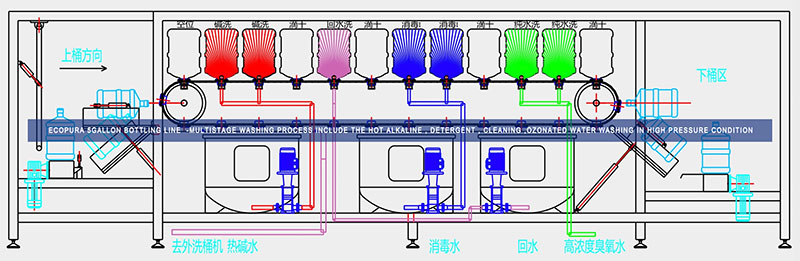

ECOPURA 5gallon bottle washing filling capping machine HSG100-HSG450 with capacity 100-450bph.

A real Hygiene filling solution for your recycling use 5Gallon bottled water business with SIEMENS PLC Control and touch Screen control. All parts that come to contact with water are manufactured in Stainless steel 304 or 316L ,Equipped S.S304 Chemical tank for multistage rinsing

The Caps elevator doses the caps into the caps unscrambler then delivery through caps chute to enter into caps washing tunnel, finished clean caps feed following the chute transferring to capping position on capping machine

Design for online 5Gallon caps cleaning & Sterilizing by multistage washing process -detergent washing & purified water washing,

Clean bottles are discharged out of washing part to filler. After entering the filler, bottles are filled contactless with qualitatively control.

A turnkey solution for 5Gallon bottling line

♦ 1.Automatic bottle decapper

♦ 2.Automatic inside & outside brusher washer

♦ 3.Automatic bottle feeder -Multistage high-pressure washing unit

♦ 4.Linear or Rotary filler & capper

♦ 5.Automatic Capsules Labeling shrinking

♦ 6.Light Inspection

♦ 7.Thin film (bag) Packing

♦ 8.Palletizer

price liquid epoxy resin filling machine

price liquid epoxy resin filling machine

Overview

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Wuhan Kefai Innovation Machinery Co., Ltd. is a manufacturer of price liquid epoxy resin filling machine with well-equipped testing facilities and strong technical force.

price liquid epoxy resin filling machine

Technical Parameter

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Model | KF01-L10 | KF01-L20 | KF01-L50 | KF01-L100 | KF01-L250 | KF01-L500 |

Filling range | 5-100ml | 10-250ml | 50-500ml | 100-1000ml | 500-2500ml | 1000-5000ml |

Air pressure range | 4-6Kg/cm² | 4-6Kg/cm² | 4-6Kg/cm² | 5-8Kg/cm² | 5-8Kg/cm² | 5-8Kg/cm² |

Filling speed | 30-35 bottles/min | 25-30 bottles/min | 20-25 bottles/min | 15-20 bottles/min | 10-15 bottles/min | 5-10 bottles/min |

Pressure | 0.4-0.6mpa | 0.4-0.6mpa | 0.4-0.6mpa | 0.5-0.8mpa | 0.5-0.8mpa | 0.5-0.8mpa |

Filling accuracy | ≤ ± 0.25-0.5% | |||||

Electrical original | 200 / 110V,50 / 60HZ | |||||

Host size | 1050*380*390mm/1150*510*450 | |||||

price liquid epoxy resin filling machine

Machine Pictures

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

price liquid epoxy resin filling machine

Machine Construction

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------

| 1)This is a brand new single/double head piston filler.All stainless steel, Brand Cylinder. |

| 2)Stainless steel sanitary tri-clamp connections, connection "T's", check valves and product cylinder ,are ideally suited for food, pharmaceutical and specialty industries. |

| 3)assembly for easy wash-down ,includes check valves and cylinder. |

| 4)Easy to maintain, ready to use. |

| 5)The filling body's assembly can be moved in the place where it's convenient for you to fill or where you wish! |

| 6)Pneumatic operation is suitable for hazardous areas. |

| 7)Easy adjusting fill volume control. |

Accessories

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

price liquid epoxy resin filling machine

Operating Principle

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------

The main components of the equipment include self-suction tube, material cylinder, cylinder, check valve, control parts, connectors, seals ect.

The equipment adopts the piston push-pull rod structure, the main cylinder to produce strong force to push-pull the piston head, through the inlet, outlet check valve action, let the stainless steel cylinder within the air discharged from the filling head, so the material cylinder to form a vacuum cavity, material cylinder into the state of negative pressure. Main cylinder push-pull rod back to the piston head, the inlet check valve opens, and the outlet check valve closes. Due to the pressure difference between inside and outside, the material will be sucked into the cylinder. This is the suction process.

When the suction process finishes, trip position rod touches a travel switch and the main cylinder stops. The machine is standby state. When the operator (manual mode) switch on the footswitch, the inlet check valve closes and the outlet check valve opens. The main cylinder push-pull rod push the piston Material from the feed cylinder is squeezed into the filling head, then filling into the packaging container, the filling process finishes.

The entire filling process includes:

1.Self-suction tube inserted in the bucket

2.Air discharging

3.Material cylinder suction

4.Filling. The machine is preliminary test (self-suction tube inserted in the bucket & air discharged), then the machine can be adjusted for filling. Setting the filling volume is set through rotating the handle to adjust piston trip to achieve.

The details of the principle of the machine are as follows:

price liquid epoxy resin filling machine

We warmly welcome you all to offer your valuable advices

to us on any aspects. Contact Us Now !

....

The sample service

1.We can send you the video of the running machine.

2.You are welcome to come to visit our company to see the machine running in our factory,we can pick you up from the station near our city.

3.If we get the permission of our customer,we can tell you our old customer contact imformation.

Customized service

1.We can design the machines according your requirements (materil ,power,filling type,bottles, and so on),at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.

2.We offer free technical support and consultation,such as draw the factory layout for you, alalyze the source water report and so on.

After-sales service

1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly.

2.When you finish the Preparation conditions ,our fast and professional after service engineer teamwill go to your factory to install the machine,give you the operating manual ,and train your employee until they can operate the machine well.

3.We provide one year warranty with spare parts free.

4.We ask the feedback from our customer and offer some help when the machine have been used for some time.

Copyright © 2025 Shenzhen EcoPura Water Equipment Co.,Ltd | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.